Polystyrene Market Size, Share & Trends Analysis Report By Resin Type (General Purpose Polystyrene (GPPS), High Impact Polystyrene (HIPS)), By Form Type (Foams, Injection Molding), By End-use, By Region, And Segment Forecasts, 2023 - 2030

- Report ID: GVR-4-68040-138-3

- Number of Pages: 134

- Format: Electronic (PDF)

- Historical Range: 2018 - 2021

- Industry:Bulk Chemicals

Polystyrene Market Size & Trends

The globalpolystyrene market size was estimated at USD 41.65 billion in 2022and is projected to grow at a compound annual growth rate (CAGR) of 4.4% from 2023 to 2030. The increasing demand for polystyrene (PS) in the packaging industry is attributed to its lightweight and excellent insulation properties, making it a preferred choice for packaging materials, particularly in the food and beverage sector. As consumers become more environmentally conscious, there is also a growing interest in sustainable and recyclable packaging solutions. Manufacturers are responding to this trend by developing bio-based and recycled PS products that meet the evolving market demands.

Moreover, another noteworthy trend in the market is the expansion of the construction and automotive industries. PS foam boards and sheets find extensive applications in insulation and construction, while PS is used in various automotive components, contributing to efforts in lightweighting. These industries are poised for growth, especially in emerging economies, which is expected to drive the demand for PS further. In addition, the electronics and consumer goods sectors continue to rely on PS for manufacturing, further bolstering market growth. However, environmental concerns and regulations related to PS waste and recycling are becoming increasingly stringent, pushing companies to invest in research and development for more sustainable PS alternatives. In conclusion, the global PS market is evolving to meet the demands of both traditional and emerging industries, driven by sustainability considerations and innovative product development.

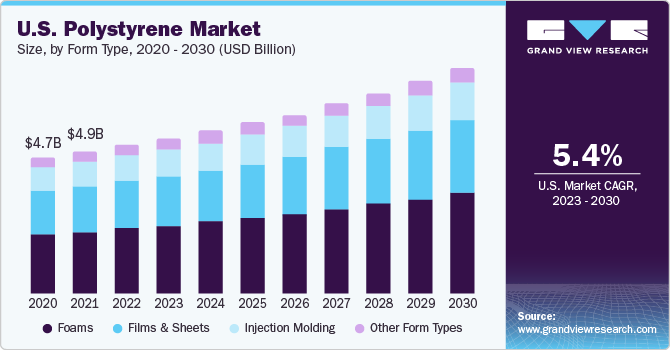

The polystyrene (PS) market in the U.S. has exhibited a dynamic landscape characterized by evolving trends and influential driving factors. The growing demand forexpanded polystyrene(EPS) foam in the building & construction industry is one of the prominent trends in the polystyrene (PS) industry. EPS foam, known for its excellent insulation properties, is extensively used in residential and commercial construction for insulation panels and roofing materials. With a rising emphasis on energy efficiency and sustainable building practices, the demand for EPS foam insulation is expected to continue its upward trajectory. In addition, the packaging sector remains a significant contributor to the PS market in the U.S. As e-commerce and food delivery services continue to expand, the need for protective packaging materials, including PS foam and rigid PS containers, has surged. Manufacturers are also focusing on developing PS products that are not only functional but also environmentally friendly to align with consumer preferences for sustainable packaging solutions.

The driving factor behind the market growth in the U.S. includes the nation's robust manufacturing sector. PS is a key component in the production of various consumer goods, such as electronics,toys, and disposable utensils, which are essential for everyday life. This consistent demand from manufacturers has been a stabilizing force in the U.S. PS market. Moreover, the automotive industry plays a pivotal role as a driving factor. PS is used in the production of various automotive components, contributing to lightweighting efforts and improving fuel efficiency in vehicles. However, it is important to note that environmental concerns and regulatory pressures are increasingly shaping the PS market in the U.S. as well. Legislation and consumer awareness around plastic waste and recycling have prompted industry players to explore sustainable alternatives and recycling initiatives, ushering in a transition toward more eco-friendly PS products in response to these evolving market dynamics.

Resin Type Insights

根据树脂类型、高抗冲聚苯乙烯(臀部) is the dominating resin type in the market and held more than 53.0% revenue share in 2022 due to its exceptional versatility, offering robust impact resistance and rigidity across various industries. HIPS is known for its robust impact resistance and rigidity, making it a preferred choice in the production of consumer goods, electronics, toys, and packaging materials. This broad utility has led to widespread adoption across various industries, contributing significantly to its market share.

Furthermore, the demand for HIPS has been boosted by its cost-effectiveness. HIPS is relatively affordable compared to some other engineeringplastics, making it an attractive choice for manufacturers looking to maintain cost-efficiency without compromising on product quality. This cost advantage has been particularly appealing in industries like consumer electronics and automotive, where high-volume production is common. In addition, the recyclability of HIPS has gained prominence in the context of sustainability and environmental concerns. As consumers and governments worldwide prioritize eco-friendly materials and recycling initiatives, HIPS' recyclability and compatibility with existing recycling infrastructure have further cemented its position as the leading resin type in the global market. In conclusion, the dominance of High Impact Polystyrene in the global market in 2022 can be attributed to its versatility, cost-effectiveness, and environmental considerations, making it a preferred choice for manufacturers across various sectors.

Form Type Insights

In terms of form type, the foams segment dominated the global market with a revenue share of more than 43.0% in 2022 due to its widespread use in insulation and packaging applications, aligning with increased demand for energy efficiency and protective shipping solutions. PS foams are widely favored for their exceptional insulating properties. This makes them a go-to choice in the construction and building industry for applications like insulation panels androofing materials. As energy efficiency continues to be a significant concern worldwide, the demand for effective insulation materials has surged, propelling the growth of PS foam products.

Furthermore, polystyrene (PS) foams have found extensive use in the packaging sector. With the expansion ofe-commerceand online retail, there has been a heightened need for protective packaging materials that can safeguard products during transit. PS foam's cushioning and shock-absorbing capabilities make it an ideal choice for shipping delicate and fragile items. In addition, the lightweight nature of PS foams helps reduce shipping costs, further enhancing their appeal in the packaging industry.

Moreover, PS foam's versatility extends beyond construction and packaging. It is utilized in various consumer goods, including disposable tableware,food containers和产品包装。它的低成本和方便production make it an economical choice for manufacturers, contributing to its dominance in the PS market. Lastly, as environmental concerns continue to drive the market, manufacturers are exploring sustainable alternatives within the PS foam category, such as biodegradable foams and recycling initiatives, ensuring that PS foam remains a formidable force in the global market.

End-use Insights

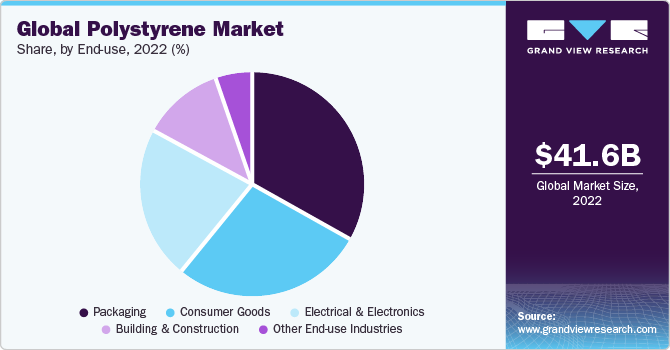

In terms of end-use, the packaging segment dominated the market in 2022 with a revenue share of more than 33.0% due to its versatile qualities, including transparency, structural integrity, and insulation, making PS a favored choice for various packaging applications, from food containers to shipping materials, meeting diverse industry needs. PS possesses a unique set of properties that make it exceptionally well-suited for various packaging applications. Its transparency allows consumers to easily see and evaluate products, which is crucial for marketing and presentation. In addition, PS offers rigidity and strength, ensuring that packaging maintains its structural integrity during transportation and handling. These characteristics are particularly important in the food and beverage industry, where PS containers and packaging materials are widely used to keep perishable goods fresh and protected.

Furthermore, the rapid growth of e-commerce and online retail has significantly boosted the demand for packaging materials, further solidifying the packaging segment's dominance. With the increasing volume of goods being shipped globally, there's a heightened need for packaging solutions that can provide both protection and cost-efficiency. PS excels in this regard due to its ability to cushion and safeguard fragile items during transit, while also being lightweight, which helps reduce shipping costs. The visibility and clarity of PS packaging enhance the aesthetic appeal of products and contribute to consumer satisfaction. While sustainability concerns have led to greater scrutiny of PS packaging, ongoing efforts to develop recyclable and environmentally friendly PS alternatives ensure that it continues to be a preferred choice for packaging applications, maintaining its dominant position in the global market. In conclusion, the packaging sector's dominance in the global market in 2022 is a result of PS's versatile properties, cost-effectiveness, and suitability for diverse packaging needs, particularly in the context of the expanding e-commerce industry and the focus on sustainable packaging solutions.

Regional Insights

Asia Pacific dominated the market in 2022 with a revenue share of more than 54.0%, which can be attributed to a combination of economic growth, industrialization, and several other key factors. One primary driver is the rapid expansion of manufacturing and packaging industries across the region. Countries in Asia Pacific, such as China, India, and Southeast Asian nations, have witnessed a surge in industrial activities and production over the past few decades. PS is a crucial material in these sectors due to its affordability and versatility. It is used extensively in the manufacturing of consumer goods, electronics, automotive components, and packaging materials. As these industries continue to grow and diversify, the demand for PS remains robust, driving the region's dominant market position.

Furthermore, Asia Pacific's population growth and rising middle-class income levels have led to increased consumption of consumer goods and packaged products. This heightened consumer demand has boosted the need for efficient and cost-effective packaging solutions, where PS plays a vital role. In addition, the region's construction sector has been booming, with urbanization and infrastructure development on the rise. PS foam boards and sheets are favored for their insulation properties, making them essential in the construction of residential and commercial buildings. As energy efficiency becomes a priority, the demand for PS foam in construction applications has surged, further contributing to the region's dominance in the market.

Moreover, the Asia Pacific region has been a hub for manufacturing PS products due to lower production costs and favorable labor conditions. This has allowed for competitive pricing and a steady supply of PS materials, attracting both domestic and international manufacturers to establish a presence in the region. While environmental concerns and sustainability are emerging challenges, Asia Pacific is also actively exploring eco-friendly alternatives and recycling initiatives to address these issues, ensuring the continued growth of the PS market in the region. In conclusion, the Asia Pacific's dominant position in the global PS market in 2022 is driven by its thriving manufacturing, packaging, and construction sectors, fueled by population growth and rising consumer demand, alongside efforts to address sustainability concerns.

Key Companies & Market Share Insights

The market has been characterized by the presence of key players along with a few medium and small regional players. Major players are continuously working on developing polymers for the production of polystyrene (PS) owing to the rising demand for PS components from end-use industries.

The global market is a highly competitive market due to the presence of major industries across the region as these companies are comparatively concentrated and fiercely competitive along with product launch, acquisitions, mergers, and collaborations. For Instance, in February 2023, INEOS Styrolution Group GmbH, one of the leading companies of styrenics launched ISCC PLUS certified bio-based polystyrene (PS) with the brand name K-Resin® ECO and tyrolux® ECO in the Americas market. Some prominent players in the global polystyrene market include:

Atlas Molded Products

Alpek S.A.B. de CV

Americas Styrenics LLC (AmSty)

BASF SE

CHIMEI

Formosa Chemicals & Fibre Corp.

INEOS Styrolution Group GmbH

Innova

KUMHO PETROCHEMICAL

LG Chem

SABIC

Synthos

Total

Trinseo

Versalis SpA

Polystyrene Market Report Scope

Report Attribute |

Details |

Market size value in 2023 |

USD 43.17 billion |

Revenue forecast in 2030 |

USD 58.36 billion |

Growth rate |

CAGR of 4.4% from 2023 to 2030 |

Base year for estimation |

2022 |

Historical data |

2018 - 2021 |

Forecast period |

2023 - 2030 |

Quantitative units |

Volume in kilotons, revenue in USD million/billion, and CAGR from 2023 to 2030 |

Report coverage |

Revenue & volume forecast, company ranking, competitive landscape, growth factors, and trends |

Segments covered |

Resin type, form type, end-use, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; MEA |

Country scope |

U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; The Netherlands; China; India; Japan; South Korea; Australia; Thailand; Malaysia; Indonesia; Vietnam; Brazil; Argentina; Saudi Arabia; UAE; South Africa |

Key companies profiled |

Atlas Molded Products; Alpek S.A.B. de CV; Americas Styrenics LLC (AmSty); BASF SE; CHIMEI; Formosa Chemicals & Fibre Corp.; INEOS Styrolution Group GmbH; Innova; KUMHO PETROCHEMICAL; LG Chem; SABIC; Synthos; Total; Trinseo; Versalis SpA |

Customization scope |

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope. |

革命制度党cing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Global Polystyrene Market Report Segmentation

This report forecasts revenue and volume growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2023 to 2030. For this study, Grand View Research has segmented the global polystyrene market report based on resin type, form type, end-use, and region:

Resin Type Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

General Purpose Polystyrene (GPPS)

High Impact Polystyrene (HIPS)

Expandable Polystyrene (EPS)

Form Type Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Foams

Films and Sheets

Injection Molding

Other Form Types

End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Packaging

Building & Construction

Electrical & Electronics

Consumer Goods

Other End-use Industries

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Netherlands

Asia Pacific

China

India

Japan

South Korea

Australia

Thailand

Malaysia

Indonesia

Vietnam

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

Frequently Asked Questions About This Report

b.The global polystyrene market size was estimated at USD 41.65 billion in 2022 and is expected to reach USD 43.17 billion in 2023.

b.The global polystyrene market is expected to grow at a compound annual growth rate of 4.4% from 2023 to 2030 to reach USD 58.36 billion by 2030.

b.Packaging accounted for the largest share of the global polystyrene market, with a revenue share of 33.69% in 2022 due to its versatile qualities, including transparency, structural integrity, and insulation, making PS a favored choice for various packaging applications, from food containers to shipping materials, meeting diverse industry needs.

b.Major players present across the polystyrene market include Atlas Molded Products, Alpek S.A.B. de CV, Americas Styrenics LLC (AmSty), BASF SE, CHIMEI, Formosa Chemicals & Fibre Corp., INEOS Styrolution Group GmbH, Innova, KUMHO PETROCHEMICAL, LG Chem, SABIC, Synthos, Total, Trinseo, Versalis SpA

b.The polystyrene market is driven by its versatility, cost-effectiveness, and demand in industries like packaging, construction, and insulation, along with growing environmental concerns pushing for more sustainable alternatives.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."