Plastic Blow Molding Machine Market Size, Share & Trends Analysis Report By Technology (Injection Stretch, Injection, Extrusion), By End-use (Packaging, Automotive), By Region, And Segment Forecasts, 2023 - 2030

- Report ID: GVR-4-68040-104-9

- Number of Pages: 190

- Format: Electronic (PDF)

- Historical Range: 2018 - 2021

- Industry:Advanced Materials

Report Overview

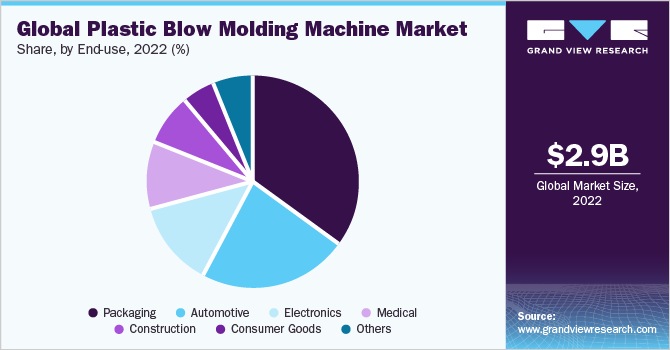

The globalplastic blow molding machine marketsizewas estimated atUSD 2.97 billion in 2022和复合年gro有望增长wth rate (CAGR) of 3.9% from 2023 to 2030. The medical industry's growing need for blow-molded plastic items and the growing significance of plastic recycling is predicted to boost market expansion throughout the projected period. Plastic blow molding machines are widely used for different applications such as concrete forms of all shapes and sizes, panels, barricades, and traffic markers in the building & construction industry. Industries such as construction, packaging, and automotive are the industries propelling the demand for plastic molding machines. Plastic blow molding machines are incorporating robotics,artificial intelligence(AI), and sensor technologies to increase productivity, decrease human error, and improve efficiency. Automation of plastic blow molding machines is anticipated to increase output capacity and reduce costs, contributing to the market's estimated revenue growth.

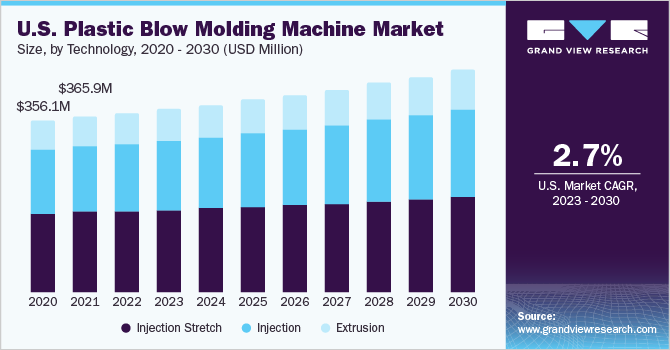

The demand for blow-molded plastics across the U.S. is majorly generated by the expanding automotive industry, on account of the popularity ofelectric vehiclesand the rise in the number of construction activities. For instance, the U.S. witnessed a growth in electric car sales from 1.0 million in 2022 to 1.6 million in 2023. The rising demand for electric vehicles is expected to significantly boost the demand for blow-molded plastic products, thereby driving market growth.

与大多数行业,COVID-19积极ly impacted the market as demand for plastic blow molding machines surged in response to the growing demand for plastic packaging for sanitizers, cleaning supplies, and beverages like water. For instance, a Spanish supplier of plastics machinery claimed that in June 2020, production in the bottle and bottling sector was 100% more than typical.

The rising demand for plastic containers is driving the demand for plastic molds, which will ultimately help the industry in the U.S. to flourish. For instance, Meredith-Springfield Associates Inc. in August 2021 announced the expansion of its manufacturing facility by 5,000 square feet. The company also installed two extrusion blow molding machines and one injection stretch blow molding equipment.

The development of the market is anticipated to be aided by a focus on recycling plastics, offsetting the detrimental effects of the prohibition of single-use plastic on the blow molding industry. For instance, in November 2020, Austria implemented mandatory targets by making a beverage reuse quota of 25% by 2025 compulsory in their Waste Management Act. With this, it became the first European country to do so.

Technology Insights

In 2022, the injection blow molding technology category accounted for 52.5% of the total market revenue share. Extrusion blow molds are less expensive than injection blow molds because the former requires less pressure. Another significant benefit of the plastic injection blow molding technology as compared to the extrusion blow mold; it involves less costly machinery.

注塑吹塑技术numerous advantages compared to other technologies., It provides a high level of dimensional accuracy, accurate neck shaping, the highest quality finish, production free from waste, crystal clear containers for pharmaceutical application, and mini weight tolerance.

挤压成型技术由基本使用ring organizations for manufacturing products with a uniform cross-section. Compared to other molding techniques, extrusion molding is inexpensive. Additionally, extrusion blow molding machines have a large production volume and can make many finished bottles and containers.

End-use Insights

The packaging application segment accounted for the largest revenue share of 34.8% in 2021, which is expected to continue over the forecast period. The rising demand forpackaged foodand drinking water is projected to fuel the need for containers, which in turn, is expected to augment the growth of plastic blow molding machines over the coming years.

Furthermore, rising demand for plastic blow-molded parts in the automotive industry is anticipated to propel the market growth. The growing demand is compelling manufacturers to expand their capabilities, for instance, in February 2022, Uniloy, Inc., a manufacturer of blow molds, acquired Century Die Co. LLC, to expand its molding capabilities for automotive parts, health, cleaning, and household goods.

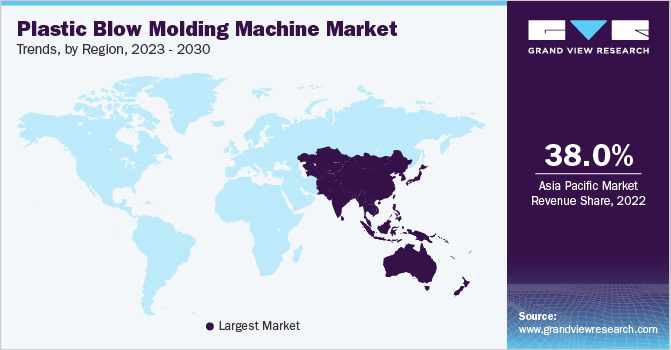

Regional Insights

Asia Pacific was the leading region in the plastic blow molding machine market and accounted for over 38% of the total revenue share in 2022. Increasing infrastructure spending, coupled with the growing automobile demand in countries such as China, India, Indonesia, and Malaysia, is expected to drive the demand for blow-molded plastics in the Asia Pacific region. Moreover, the rising demand from the packaging industry is propelling market growth in the region. For instance, in December 2021, Mumbai-based Mahika Packaging announced it to double its tube-making capacity in FY 2022-23. The company supplies its products to cater to the packaging needs of the cosmetic and pharmaceutical industries.

Furthermore, COVID-19 the pandemic augmented investments in disinfectants and sanitizers, which positively influenced product demand in North America. For instance, in January 2021, the Ontario government provided USD 0.79 million to Merit Precision to boost the production of sanitizers and disinfectants. To complete the demand, Merit Precision invested in two blow-molding lines and tooling, necessary for the infrastructure.

Key Companies & Market Share Insights

The industry is extremely competitive due to the presence of both international and local players. Plastic blow molding machine manufacturers use a variety of strategies to increase market penetration and meet the dynamic technological demands of end-use industries, such as packaging, automotive, electronics, medical, construction, consumer goods, and others.

For instance, in March 2023, Jagmohan Pla-Mach Pvt. Ltd acquired additional land of 50,000 square feet to expand its existing site. The company expanded its existing facility which is in Asagaon to Mumbai-Nashik Highway. The additional floor area will be used to increase the product selection and boost the output of injection blow molding machines & high-velocity-speed auto deflashing blow molding machines for multilayer & mono-layer segments. Some prominent players in the global plastic blow molding machine market include:

BLOW ENTERPRISES

Chia Ming Machinery Co., Ltd

GOLFANG Mfg. & Development Co., Ltd

Jagmohan Pla-Mach Pvt. Ltd

Jiangsu victor machinery co., LTD

Jomar Corp

NISSEI ASB MACHINE CO., LTD

Polymechplast Machines Ltd

Sumitomo Heavy Industries, Ltd

The Japan Steel Works, LTD

Plastic Blow Molding Machine Market Report Scope

Report Attribute |

Details |

Market size value in 2023 |

USD 3.07 billion |

Revenue forecast in 2030 |

USD 4.04 billion |

Growth Rate |

CAGR of 3.9 % from 2023 to 2030 |

Base year for estimation |

2022 |

Historical data |

2018 - 2021 |

Forecast period |

2023 - 2030 |

Quantitative units |

Revenue in USD million/billion, CAGR from 2023 to 2030 |

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, trends |

Segments covered |

Technology, end-use, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country Scope |

U.S.; Canada; Mexico; Germany; France; Italy; UK; China; India; Japan; Australia; Brazil; Argentina; Saudi Arabia; South Africa |

Key companies profiled |

BLOW ENTERPRISES; Chia Ming Machinery Co., Ltd; GOLFANG Mfg. & Development Co., Ltd; Jagmohan Pla-Mach Pvt. Ltd; Jiangsu victor machinery co., LTD; Jomar Corp; NISSEI ASB MACHINE CO., LTD |

Customization scope |

Free report customization (equivalent up to 8 analysts' working days) with purchase. Addition or alteration to country, regional & segment scope. |

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

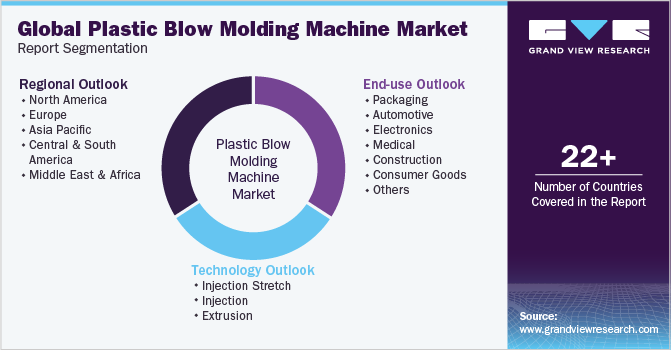

Global Plastic Blow Molding Machine Market Report Segmentation

This report forecasts revenue growth and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the plastic blow molding machine market report based on technology, end-use, and region:

Technology Outlook (Revenue, USD Million, 2018 - 2030)

Injection Stretch

Injection

Extrusion

End-use Outlook (Revenue, USD Million, 2018 - 2030)

Packaging

Automotive

Electronics

Medical

Construction

Consumer Goods

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

UK

France

Italy

Asia Pacific

China

India

Japan

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

South Africa

Frequently Asked Questions About This Report

b.The global plastic blow molding machine market size was estimated at USD 2.97 billion in 2022 and is expected to reach USD 3.07 billion in 2023.

b.The global plastic blow molding machine market, in terms of revenue, is expected to grow at a compound annual growth rate of 3.9% from 2023 to 2030 and reach USD 4.04 billion by 2030.

b.Asia Pacific dominated the plastic blow molding machine Market with a revenue share of 38.6% in 2022. Increasing infrastructure spending, coupled with the growing automobile demand in countries such as China, India, Indonesia, and Malaysia, is expected to drive the demand for blow-molded plastics in the Asia Pacific region.

b.Some of the key players operating in the plastic blow molding machine market include BLOW ENTERPRISES, Chia Ming Machinery Co., Ltd, GOLFANG Mfg. & Development Co., Ltd, Jagmohan Pla-Mach Pvt. Ltd, Jiangsu victor machinery co., LTD, Jomar Corp, NISSEI ASB MACHINE CO., LTD, Polymechplast Machines Ltd, among others.

b.The key factors that are driving the plastic blow molding machine market include the rising demand for plastic blow molded products in the medical sector coupled with the increasing importance of plastic recycling are expected to augment the market growth in the forecast period.