Pharmaceutical Collaborative Robots Market Size, Share & Trends Analysis Report By Application (Picking & Packaging, Laboratory Applications), By End-use (Pharmaceutical Companies, Research Laboratories), And Segment Forecasts, 2023 - 2030

- Report ID: GVR-4-68040-127-0

- Number of Pages: 120

- Format: Electronic (PDF)

- Historical Range: 2016 - 2021

- Industry:Healthcare

Report Overview

The globalpharmaceutical collaborative robots market sizewas estimated atUSD 64.90 million in 2022,预计年复合增长的恶性肿瘤h rate (CAGR) of 9.7% from 2023 to 2030. In the pharmaceutical industry, the imperative of regulatory compliance and quality assurance underscores the need for precision in manufacturing processes. Collaborative robots are pivotal in ensuring compliance by reducing errors and inconsistencies and concurrently elevating product quality through controlled and consistent operations. In addition, the scarcity of skilled labor and the pursuit of enhanced workforce efficiency further propel the integration of pharmaceutical collaborative robots, streamlining operations by automating repetitive tasks and enabling human workers to dedicate their skills to higher-value activities, thus augmenting overall productivity and operational effectiveness.

Collaborative robots, often referred to as cobots, are advanced robotic systems designed to work collaboratively with humans in shared workspaces. Unlike traditional industrial robots that operate in isolated environments, cobots are equipped with sensors, safety features, and user-friendly interfaces that enable safe and efficient interaction with human workers. In the healthcare industry, particularly in pharmaceutical settings, cobots are increasingly utilized for various tasks due to their precision, adaptability, and ability to work alongside human operators. Regarding pharmaceutical laboratories, cobots represent advanced robotic systems engineered for seamless and cooperative interaction with human workers. Cobots have garnered popularity in the pharmaceutical sector due to their adaptability and aptitude for close collaboration with human operators.

pharmaceutica cobots的主要好处l industry is their capacity to augment human labor, resulting in heightened efficiency and productivity within production processes. By integrating cobots into operational frameworks, pharmaceutical enterprises can expedite production timelines and bolster output, all while upholding stringent benchmarks for product quality. Moreover, cobots possess the potential to elevate worker safety by undertaking hazardous and repetitive tasks that might otherwise jeopardize the well-being of human personnel. The pandemic disrupted global supply chains, potentially affecting pharmaceutical ingredients. Cobots, proficient in material handling, aided in maintaining manufacturing and distribution. To adhere to safety measures, such as social distancing, pharmaceutical companies turned to cobots to ensure worker safety while sustaining operational efficiency.

The escalated demand for medical supplies forced pharmaceutical companies to employ cobots for rapid production scaling, addressing urgent healthcare needs. Amidst workforce shortages caused by lockdowns, cobots handled routine tasks, allowing remote human workers to concentrate on critical production aspects. Cobots' precision in handling and sensing capabilities facilitated COVID-19 research, aiding accurate experimentation and sample handling. The fast-paced advancement of technology profoundly impacts various industries, particularly the pharmaceutical sector, where adaptability to emerging technologies is vital. Cobots exemplify a transformative development that reshapes pharmaceutical competitiveness and innovation. Cobots have undergone significant enhancements in capabilities, functionality, and user-friendliness, driven by continuous R&D.

These advancements, powered by AI,machine learning(ML), sensors, and advanced control algorithms, empower cobots to execute intricate tasks precisely. Moreover, improved user interfaces democratize automation, enabling a broader range of employees to optimize processes effectively. While cobots offer numerous advantages in the pharmaceutical industry, there are several key constraints to their widespread adoption. The initial investment cost can be substantial, including purchasing & integrating cobots and training personnel for their operation. Moreover, cobots must adhere to strict regulatory standards in the pharmaceutical sector, necessitating comprehensive validation processes and documentation to ensure compliance with safety and quality requirements, which can lengthen implementation timelines.

Application Insights

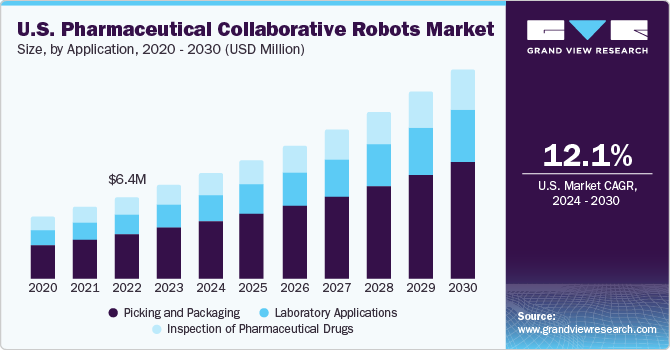

The application segment comprises picking & packaging, inspection of pharmaceutical drugs, and laboratory applications. The picking and packaging segment emerged as the dominant force in the market, capturing the largest share of 54.4% in 2022. The growth can be attributed to this segment's critical role in the supply chain and manufacturing processes. Picking and packaging ensure products are efficiently sorted, prepared, and dispatched. With the increasing demand for streamlined logistics, rapid e-commerce growth, and the need for precision in delivering products to consumers, companies are prioritizing automation solutions in these areas.

As a result, investments in collaborative robots for picking and packaging have surged, bolstering the segment's market dominance in 2022. The segment is also expected to witness the fastest growth at a CAGR of 10.3% during the forecast period. This growth can be attributed to robots' ability to enhance precision and efficiency and address intricate material handling issues. Moreover, the pick-and-place approach offers these benefits and conserves floor space by operating within a confined work envelope, effectively optimizing workspace utilization. This trend reflects the industry's commitment to maximizing operational efficiency while ensuring space optimization.

End-use Insights

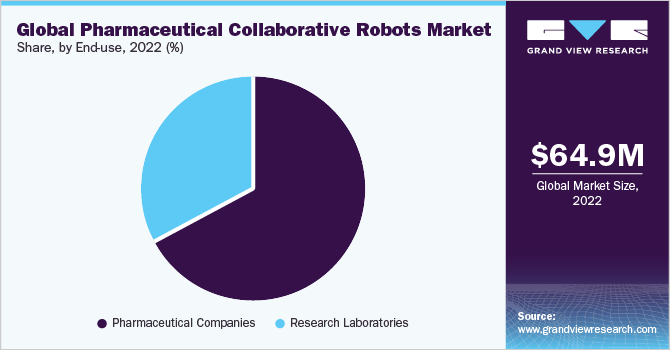

The end-use segment comprises pharmaceutical companies and research laboratories. The pharmaceutical companies segment dominated the market capturing the largest share of 67.7% in 2022. A rise in the adoption of robotics in drug discovery and development contributes to this trend. Furthermore, pharmaceutical firms' engagement inpersonalized medicineinitiatives fueled the segment's growth. Research laboratories are expected to experience notable expansion during the projected period due to the automation's capacity to handle repetitive tasks, such as transferring test tubes and fluids, in drug discovery endeavors, thereby enhancing precision and consistency.

快速的市场预计也将见证t growth at a CAGR of 10.1% during the forecast period. The industry's unwavering focus on research and development fosters a consistent flow of enhanced products, reinforcing its market supremacy. Meeting rigorous regulatory standards for safety and efficacy further bolsters the credibility of pharmaceutical offerings. Global reach, robust distribution networks, and strategic partnerships amplify pharmaceutical companies' influence, while collaborations with healthcare providers, academic institutions, and government agencies expand their customer base.

Regional Insights

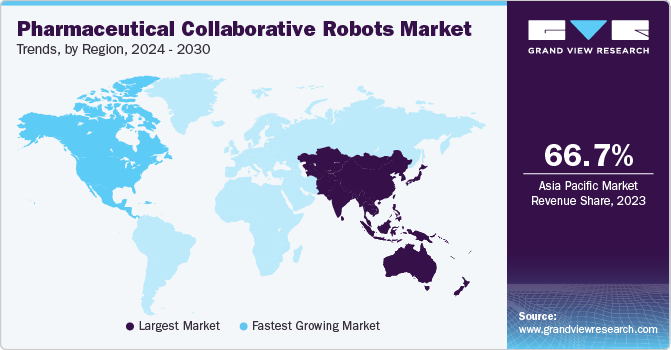

Asia Pacific accounted for the largest share of around 66.9% in 2022 and is anticipated to witness lucrative growth during the forecast period. This is attributed to many local pharmaceutical companies in countries, such as Japan. The regional market is experiencing notable growth, driven by the rising number of industries in the area that are embracing automation to optimize returns on investment. China is witnessing a surge in the production, sale, and trade of cobots, positioning it as a prominent player in the Asia Pacific cobots market. On the other hand, North America is expected to witness the fastest CAGR of 12.2% over the forecast period.

The expansion of the market in the region can be credited to the substantial volume of robot installations in the region. As per the International Federation of Robotics, the American region recorded a 20% growth rate in the deployment of robots, marking a new record high for the sixth consecutive year. Consequently, North America has a high number of pharmaceutical robots, a trend projected to escalate due to a rise in the count of pharmaceutical enterprises in the region. The IFR also noted North America's efforts to fortify its pharmaceutical manufacturing capabilities for global competitiveness by embracing automation within its production facilities.

Key Companies & Market Share Insights

The market was experiencing growth as more pharmaceutical companies recognized the benefits of integrating cobots into their operations. Established industrial robotics companies and specialized automation providers were entering the market to cater to the industry's specific needs. In January 2020, ABB invested in MTEK, a robotics solution and software start-up in Sweden, as part of its venture capital initiative. This partnership aimed to expand the capabilities of collaborative robots, specifically ABB's YuMi, by jointly developing and implementing advanced software, solutions, and services to enable intelligent and real-time collaborative production. The competitive landscape also saw collaborations between cobot manufacturers and pharmaceutical companies to co-develop customized solutions.

These collaborations aimed to create cobots that could seamlessly integrate with pharmaceutical manufacturing processes and meet industry-specific requirements. For instance, in June 2022, Becton, Dickinson, and Company, in collaboration with Frazier Healthcare Partners, finalized an official agreement for BD's acquisition of Parata Systems, a forward-thinking supplier of pharmacy automation solutions, for a total of USD 1.525 billion. Parata's assortment of inventive pharmacy automation solutions drives the expansion of a network of pharmacies, aiming to lower expenses, elevate patient safety, and enhance the overall patient journey.

Similarly, in July 2020, Canada's SNC-Lavalin and Kinova joined forces through a two-year collaboration to implement robotic solutions within the nuclear industry. SNC-Lavalin seamlessly integrated Kinova's technology into a patented, certified solution, facilitating the secure deployment of collaborative robots in various settings, including gloveboxes. These innovations hold the promise of being applicable across numerous nuclear gloveboxes worldwide, enhancing operator safety and potentially boosting productivity. Some of the key players in the global pharmaceutical collaborative robots market include:

ABB Ltd.

Universal Robots A/S

Mitsubishi Electric Corporation

Kuka AG

Kawasaki Heavy Industries Ltd.

Yaskawa Electric Corporation

Denso Wave, Inc.

FANUC America Corporation

Pharmaceutical Collaborative Robots MarketReport Scope

Report Attribute |

Details |

Market size value in 2023 |

USD 73.73 million |

Revenue forecast in 2030 |

USD 140.58 million |

Growth rate |

CAGR of 9.7% from 2023 to 2030 |

Base year for estimation |

2022 |

Historical data |

2016 - 2021 |

Forecast period |

2023 - 2030 |

Quantitative units |

Revenue in USD million and CAGR from 2023 to 2030 |

Report coverage |

Revenue, company ranking, competitive landscape, growth factors, and trends |

Segments covered |

Application, end-use, region |

Regional scope |

北美;欧洲;亚太地区;拉丁美洲; MEA |

Country scope |

U.S.; Canada; Germany; UK; Spain; Italy; France; Norway; Sweden; Denmark; Japan; China; India; Australia; South Korea; Thailand; Brazil; Mexico; Argentina; South Africa; Saudi Arabia; UAE |

Key companies profiled |

ABB Ltd.; Universal Robots A/S; Mitsubishi Electric Corp.; Kuka AG; Kawasaki Heavy Industries Ltd.; Yaskawa Electric Corp.; Denso Wave, Inc.; FANUC America Corp. |

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope |

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Global Pharmaceutical Collaborative Robots MarketReport Segmentation

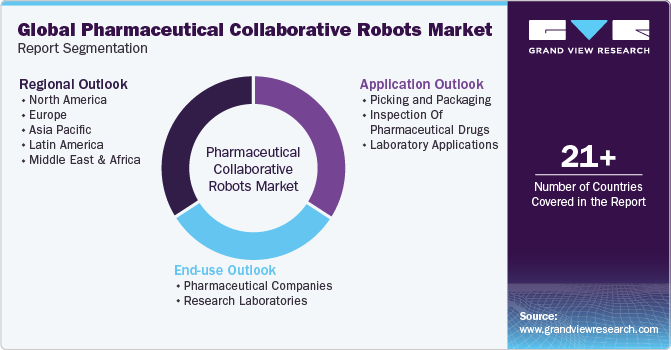

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest trends in each of the sub-segments from 2016 to 2030. For this study, Grand View Research, Inc. has segmented the pharmaceutical collaborative robots market report on the basis of application, end-use, and region:

Application Outlook (Revenue, USD Million, 2016 - 2030)

Picking & Packaging

Inspection of Pharmaceutical Drugs

Laboratory Applications

End-use Location Outlook (Revenue, USD Million, 2016 - 2030)

Pharmaceutical Companies

Research Laboratories

Regional Outlook (Revenue, USD Million, 2016 - 2030)

North America

U.S.

Canada

Europe

UK

Germany

France

Italy

Spain

Norway

Denmark

Sweden

Asia Pacific

Japan

China

India

Australia

South Korea

Thailand

拉丁美洲

Brazil

Mexico

Argentina

MEA

South Africa

Saudi Arabia

UAE

Frequently Asked Questions About This Report

b.The global pharmaceutical collaborative robots market is expected to grow at a compound annual growth rate of 9.7% from 2023 to 2030 to reach USD 140.58 million by 2030.

b.The global pharmaceutical collaborative robots market size was estimated at USD 64.9 million in 2022 and is expected to reach USD 73.73 million in 2023.

b.The picking and packaging segment emerged as the dominant force in the market, capturing the largest share of 54.4% in 2022. The growth can be attributed to this segment's critical role in the supply chain and manufacturing processes. Picking and packaging ensure products are efficiently sorted, prepared, and dispatched. With the increasing demand for streamlined logistics, rapid e-commerce growth, and the need for precision in delivering products to consumers, companies are prioritizing automation solutions in these areas. As a result, investments in collaborative robots for picking and packaging have surged, bolstering the segment's market dominance in 2022.

b.Some of the key players in the market include ABB Ltd., Universal Robots A/S, Mitsubishi Electric Corporation, Kuka AG, Kawasaki Heavy Industries Ltd., Yaskawa Electric Corporation, Denso Wave, Inc., and FANUC America Corporation.

b.制药合作机器人市场witnessing a surge in demand as the industry embraces automation to enhance efficiency and compliance. Rapid technological advancements have led to developing more versatile and user-friendly cobots that seamlessly integrate into pharmaceutical workflows. These robots are addressing challenges such as labor shortages, intricate regulatory requirements, and the need for flexible manufacturing.