Pharmaceutical Coating Equipment Market Size, Share & Trends Analysis Report By Coating Type, By Equipment Type (Perforated Coating Pan), By Region, And Segment Forecasts, 2022 - 2030

- Report ID: GVR-4-68039-970-3

- Number of Pages: 150

- Format: Electronic (PDF)

- Historical Range: 2017 - 2020

- Industry:Advanced Materials

Report Overview

The global pharmaceutical coating equipment market size was valued at USD 0.81 billion in 2021 and is expected to expand at a compounded annual growth rate (CAGR) of 5.2% from 2022 to 2030. The expeditious growth of the pharmaceutical industry, rapid adoption of orphan drugs, and increasing research and development (R&D) investment activities are anticipated to drive the market growth. The supply chain was disrupted due to regulatory restrictions on transportation. With delays to trial enrollment, data collection, data analysis, and industrial closures, the clinical trials and drug development process were delayed. However, the demand for drug development to combat the COVID-19 infection has grown rapidly and positively impacted the pharmaceutical coating market.

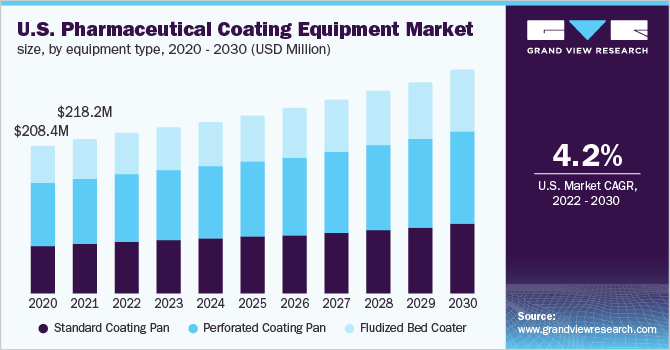

The COVID-19 pandemic is changing the market in the U.S., as businesses in this industry undertook strategic acquisitions and capacity development to satisfy the rising demand for pharmaceutical products. The disruption has handicapped the U.S. market extensively resulting in several challenges in the supply chain of a lot of essential products, but an upsurge in the healthcare sector significantly to the pharma industry.

Pharmaceutical coating demand increased considerably during the pandemic as pharmaceutical companies and governments around the world worked hard to combat the COVID-19 pandemic. The rising demand has created significant opportunities for pharmaceutical manufacturers. As a result, it increased the production and demand for pharmaceutical coating.

The pharmaceutical industry segment is driven by a rise in the prevalence of diseases that need tablet-based formulations for treatment, an increase in demand for pharmaceutical tablet coatings, and an increase in the number of drugs marketed as tablet formulations. Manufacturers of pharmaceutical tablet coatings are generating incremental opportunities in the global market.

The high growth rates in demand are attributed to factors such as the rapidly expanding middle class, government incentives for the provision of drugs at lower cost, expansions by private firms, and governments allowing FDI penetration in untapped markets. Leading coating manufacturers adopt dual/multiple sourcing strategies for a stable and continuous supply of raw materials. This, in turn, is expected to propel the demand for the pharmaceutical coating market.

Coating Type Insights

Film coating equipment dominated the market and accounted for 43.3% of the global revenue share in 2021. Demand for film-coated tablets is high in the pharmaceutical industry owing to shorter processing time and fairly thin coats compared to other types of coatings. Pharmaceutical applications of tablet film coatings have increased in recent times, creating value-grab opportunities for manufacturers.

糖衣过程涉及到大量的专业cesses, including sealing, sub-coating, polishing, dyeing, and polishing. Sugar coating is a good method for coating pills since it reduces the possibility of medication blunders. It uses pigments/colors to identify and enhances patient compliance through aesthetic appeal.

Microencapsulation is widely used in the healthcare and pharmaceutical sector for controlled drug delivery. Pharmaceutical companies generally utilize microencapsulation technology to disguise the unpleasant taste of medications and to offer targeted and controlled distribution. The growing recognition of microencapsulated materials in the pharmaceutical industry is expected to have a positive impact on industry growth.

据估计,有机镀膜段register a CAGR of 4.0% over the forecast period. As most polymers are soluble in a wide range of organic solvents, the organic solvent-based coating offers a choice of usable polymer options. In addition, pharmaceutical industries are paying attention to developing formulations with an organic film coating.

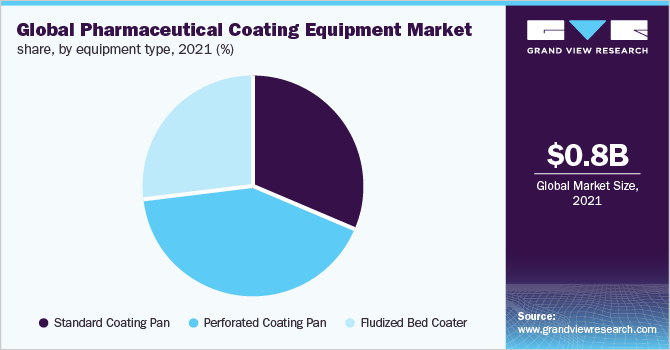

Equipment Type Insights

Standard coating pan equipment dominated the market and accounted for 31.4% of the global revenue share in 2021. The standard coating pan, which is also known as the conventional pan system is a common accessory in most pharmaceutical industries as it provides faster coating and an even distribution of the coating solution.

Many pharmaceutical companies choose perforated coating pans. This type of tablet coating equipment often features a fully or partially perforated drum. The drum of this tablet coater, like the standard coating pan, spins on a horizontal axis. The drying of coating material by a perforated coating system is better as compared to other conventional methods.

The fluidized bed coater equipment type segment is estimated to register a CAGR of 6.1% over the forecast period. Fluidized bed processes are one of the most efficient methods for producing thick-film coatings. They offer 100% transfer efficiency as well as cheaper initial and ongoing maintenance expenses. They may also cover an entire rack of components in a single dip.

The process is highly effective because it uses core particles that are not completely flat and uses small droplet sizes to coat them. This guarantees that the coating solution atomizes and sticks to the particles' surfaces without producing agglomeration. Fluidized bed coating can also generate high-quality, homogenous coatings that are highly resistant to moisture and abrasion.

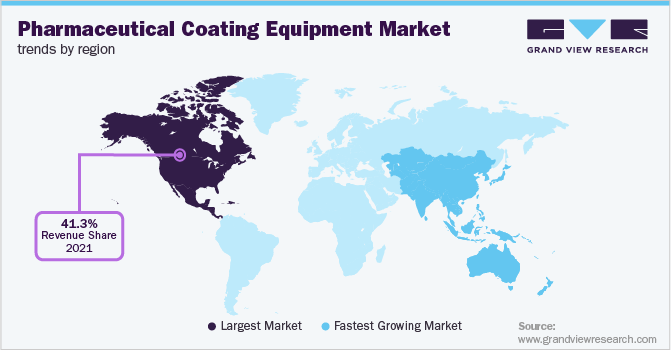

Regional Insights

North America region dominated the market and accounted for 41.3% in 2021. The development of innovative pharmaceutical products, generics, andbiosimilars, coupled with the profitable presence of key competitors with huge production capacities, will drive the market for pharmaceutical coating in North America.

Europe is anticipated to be a promising region for the future market. Availability of the giant pharmaceutical players and their capabilities for large-scale manufacturing and growing inclination toward efficient drugs and other related products along with the generics and biosimilars has led to the increase in the demand for the product thereby supporting the growth of the market.

Asia Pacific region is estimated to register a CAGR of 6.6% over the forecast period. An increase in the number of companies setting up manufacturing units in the region, and favorable government regulations coupled with low labor & manufacturing costs are projected to drive the pharmaceutical coating equipment market in the Asia Pacific during the forecast period.

Pharmaceuticals and the healthcare sector will see robust demand in the mid-and long-term, due to a rapid change in demographics Moreover, an increase in collaborations between pharmaceutical companies and outsourcing companies in Latin America for developing COVID-19 treatments is boosting the pharmaceutical coating equipment market growth.

Key Companies & Market Share Insights

The manufacturers adopted several strategies, including acquisitions, mergers, joint ventures, new product developments, and geographical expansions, to enhance market penetration and cater to the changing technological requirements from various coating such as sugar, film, seafood, microencapsulation, dip, and vacuum dip coating.

医药制造业的转移焦点to emerging markets along with the increasing outsourcing of operations to other countries present significant opportunities for market growth. Additionally, the rising focus on technological advancements in niche market areas also offers significant growth opportunities for players operating in the pharmaceutical coating market. Some prominent players in the global pharmaceutical coating equipment market include:

Ohara Technologies

ACG

Glatt GmbH

Romaco Group

Thomas Processing LLC

GEA Group Aktiengesellschaft

Syntegon Technology GmbH

L.B. Bohle Maschinen und Verfahren GmbH

DIOSNA (LINXIS Group)

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Pharmaceutical Coating Equipment Market Report Scope

Report Attribute |

Details |

Market size value in 2022 |

USD 0.85 billion |

Revenue forecast in 2030 |

USD 1.27 billion |

Growth rate |

CAGR of 5.2% from 2022 to 2030 |

Base year for estimation |

2021 |

Historical data |

2017 - 2020 |

Forecast period |

2022 - 2030 |

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends |

Segments covered |

Coating type, equipment type, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country Scope |

U.S.; Canada; Mexico; Germany; France; Italy; U.K.; China; Japan; India; South Korea; Brazil; Argentina; South Africa; Saudi Arabia |

Key companies profiled |

Ohara Technologies, ACG ; Glatt GmbH;Romaco Group; Thomas Processing LLC; GEA Group Aktiengesellschaft; Syntegon Technology GmbH; L.B. Bohle Maschinen und Verfahren GmbH; DIOSNA (LINXIS Group); GEBRÜDER LÖDIGE MASCHINENBAU GMBH; Freund-Vector Corporation; I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A.; SaintyCo. |

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

定价和purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Global Pharmaceutical Coating Equipment Market Segmentation

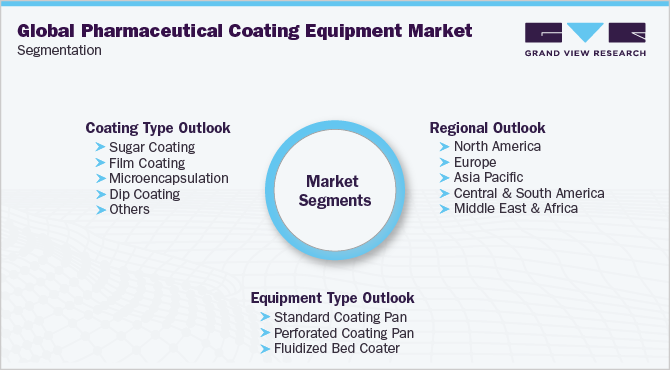

This report forecasts revenue growth at global, regional & country levels and provides an analysis on the industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global pharmaceutical coating equipment market report on the basis of coating type, equipment type, and region:

Coating Type Outlook (Revenue, USD Million, 2017 - 2030)

Sugar Coating

Film Coating

Microencapsulation

Dip Coating

Others

Equipment Type Outlook (Revenue, USD Million, 2017 - 2030)

Standard Coating Pan

Perforated Coating Pan

Fluidized Bed Coater

Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Asia Pacific

China

Japan

India

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

South Africa

Saudi Arabia

Frequently Asked Questions About This Report

b.The global pharmaceutical coating equipment market size was estimated at USD 0.81 billion in 2021 and is expected to be USD 0.85 billion in 2022

b.The pharmaceutical coating equipment market, in terms of revenue, is expected to grow at a compound annual growth rate of 5.2 % from 2022 to 2030 to reach USD 1.27 billion by 2030

b.North America dominated the pharmaceutical coating equipment market with a revenue share of 41.3 % in 2021. The development of innovative pharmaceutical products, coupled with the profitable presence of key competitors with huge production capacities, will drive the market for pharmaceutical coating in North America.

b.Some of the key players operating in the pharmaceutical coating equipment market include: Ohara Technologies , ACG , Glatt GmbH,Romaco Group, Thomas Processing LLC, GEA Group Aktiengesellschaft, Syntegon Technology GmbH, L.B. Bohle Maschinen und Verfahren GmbH, DIOSNA (LINXIS Group), GEBRÜDER LÖDIGE MASCHINENBAU GMBH, Freund-Vector Corporation, I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A., SaintyCo.

b.Key factors that are driving the pharmaceutical coating equipment market growth include Expeditious growth of the pharmaceutical industry, rapid adoption of orphan drugs, increasing research and development (R&D) investment activities is anticipated to drive the market growth