North America Digital Transformation in Manufacturing Market Size, Share & Trends Analysis Report By Type, By Deployment (Hosted, On-premise), By Enterprise Size (Large, SMEs), And Segment Forecasts, 2018 - 2025

- Report ID: GVR-2-68038-558-8

- Number of Pages: 110

- Format: Electronic (PDF)

- Historical Range: 2014 - 2016

- Industry:Technology

Industry Insights

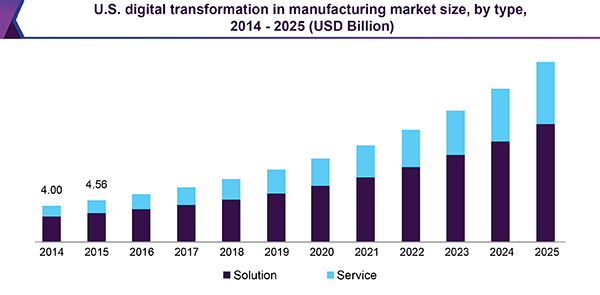

The North America digital transformation in the manufacturing market size was valued at USD 7.30 billion in 2017. It is anticipated to witness a CAGR of 17.2% over the forecast period. The market is expected to gain significant momentum over the coming years owing to surging demand for knowledge-based manufacturing equipment that features simulation capabilities, advanced control, and sensing. Additionally, the growing penetration of theInternet of Things (IoT)and the adoption of cloud platforms in production processes are projected to spur the growth of the market over the forecast period.

Furthermore, IoT-enabled manufacturing plants allow manufacturing companies to optimize business operations, product and services innovation, and enhance supply chain and logistics management. Thus, manufacturers from different sectors such as industrial equipment, healthcare, defense, and electronics are seeking solutions that cater to specific needs.

Automation has been constantly evolving over the past few years, enabling manufacturers to simultaneously manage multiple tasks. The emergence ofArtificial Intelligence (AI)is the major factor promoting industrial automation, where processes are restructured for smarter, real-time, and efficient decision-making in production. Growing penetration of IoT is enabling manufacturers to modernize their operations at two basic levels, namely in providing connected products and connecting supply chains.

弗吉尼亚州IoT-enabled传感器提供的发展rious benefits such as digital network proficiency and self-diagnostics help the manufacturing industries to meet distinct industry requirements. Furthermore, increasing spending on research and development activities by sensor providers facilitates the development of advanced sensors that meet the requirements of different industrial plants.

Numerous initiatives at the industry level have been promoting and advertising IoT applications and their use cases. For example, the U.S. government launched a program called the National Network for Manufacturing Innovation (NNMI) that aimed to boost the adoption of advanced manufacturing technologies for manufacturing innovative products. Additionally, ecosystems of IoT solution providers, including hardware, software, and services vendors are working toward a unified and common goal of increasing awareness and adoption of IoT.

However, the growing threat of cyberattacks in North America is estimated to hinder the growth of the market over the forecast period. Exchange of large volumes of information between shop floors and cloud and among stakeholders across a supply chain enhances the vulnerability of systems to threats from internet sabotage attacks. Interconnected manufacturing processes increase exposure to security risks, which have financial and critical impacts on connected production processes.

Type Insights

解决方案部分可能在3月ket over the forecast period owing to various benefits offered by digitalization, including improving productivity, optimizing return on investment (ROI), and reducing cost for businesses across the manufacturing sector. Analytics-based solutions find a wide range of applications across various industries such as aerospace & defense, pharmaceutical, life science, oil and gas, and automotive.

These solutions can be used for predictive maintenance systems in the manufacturing sector to reduce downtime and increase production. Additionally, predictive analytics help manufacturers to understand issues related to machines and this helps them increase productivity and simultaneously boost the profitability of organizations.

The use of cloud computing solutions in manufacturing helps industries to control and monitor their plant processes by synchronizing data through a single point. The solution also allows users to access information via the internet.

Cloud computing is considered to be a key solution for digital transformation. The need for faster deployment, development, and delivery of solutions, along with higher flexibility, is further bolstering the demand for cloud computing solutions.

Deployment Insights

The hosted segment is poised to post a remarkable CAGR during the forecast period owing to the flexibility provided by this type of deployment. It allows users to access connected manufacturing machines from remote locations through mobile devices as well as desktop computers. Additionally, it offers benefits such as cost efficiency, easy accessibility and deployment, and minimal upgrade and maintenance requirement.

The on-premise segment is anticipated to experience healthy growth over the forecast period as it is expected to remain the preferred method of deployment among small & medium enterprises (SMEs). SMEs are reluctant to switch to the cloud owing to a lack of awareness of its advantages. However, this scenario is projected to change gradually over the forecast period.

Enterprise Size Insights

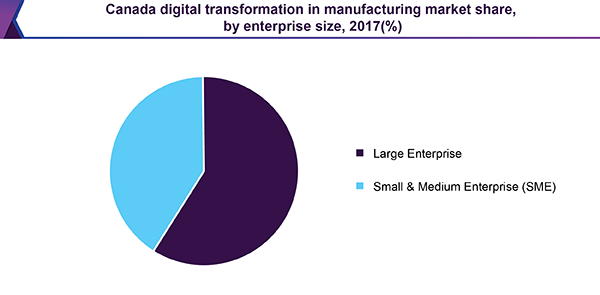

A growing number of SMEs in the region are driving the demand for deployment of digital manufacturing solutions owing to their business optimization capabilities. Furthermore, increasing government funding for SMEs to deploy digital manufacturing solutions is estimated to supplement the growth of the SME segment.

大型企业市场主导的朝鲜merica digital transformation in the manufacturing market in terms of revenue and reached USD 4.35 billion in 2017. Large enterprises are making significant investments in digital manufacturing processes to enhance or maintain their market position in a highly competitive environment. They are also readily adopting advanced technologies to cope with changing industry dynamics. Moreover, they are undertaking various strategic initiatives such as partnerships and mergers & acquisitions to adopt new technologies for increasing the efficiency of production processes.

Country Insights

North America is likely to register significant growth over the forecast period, owing to increasing investments in Internet-of-Things (IoT), enterprise resource planning (ERP), and big data. Companies operating in North America are increasingly opting for the digitization of legacy systems. Furthermore, manufacturing companies are making considerable investments in digital technologies and related assets to increase production efficiency as well as to reduce operational costs.

Governments in the region are investing in research and development activities to set up advanced sensors network, process controls, and data analytics in manufacturing companies to improve productivity and energy-efficiency. Manufacturers in Canada are making investments for transforming factory operations into digital factory operations. They are primarily focusing on automation and robotics, supply chain collaboration, and smart floor sensors. As a result, the market in Canada is poised to exhibit a phenomenal CAGR during the forecast period.

North America Digital Transformation in Manufacturing Market Share Insights

Key players in the industry include ABB Ltd.; Dassault Systemes; Emerson Electric Co.; Fanuc Corporation; General Electric Company; Honeywell International, Inc.; Mitsubishi Electric Corporation; Rockwell Automation, Inc.; Robert Bosch GmbH; Schneider Electric SE; Siemens AG; and Yokogawa Electric Corporation.

The key players are focusing on developing advanced automation solutions for manufacturing companies. For instance, in June 2018, ABB Ltd. launched a commercial, modular-enabled process automation solution. The solution enables process industries to minimize costs and increase flexibility with the ability to adapt to changing consumer demands. It is ideal for biotech manufacturers, pharmaceutical plants, fine chemical factories, and food and beverage industries.

Companies in North America are focusing on improving production processes to provide customized products based on consumers' demands. Consumers in the region are increasingly seeking products that are as intuitive as smartphones. These expectations are compelling manufacturers to deploy digital transformation solutions across industrial processes.

Report Scope

Attribute |

Details |

The base year for estimation |

2017 |

Actual estimates/Historical data |

2014 - 2016 |

Forecast period |

2018 - 2025 |

Market representation |

Revenue in USD Billion and CAGR from 2018 to 2025 |

Country scope |

U.S. and Canada |

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

15% free customization scope (equivalent to 5 analyst working days) |

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization |

Segments Covered in the Report

This report forecasts revenue growth at regional and country levels and provides an analysis of the industry trends in each of the sub-segments from 2014 to 2025. For this study, Grand View Research has segmented the North America digital transformation in manufacturing market reports based on type, deployment, enterprise size, and country.

Type Outlook (Revenue, USD Billion, 2014 - 2025)

Solution

Analytics

Cloud Computing

Mobility

Social Media

Others

Service

Implementation and Integration Services

Professional and Consulting Services

Deployment Outlook (Revenue, USD Billion, 2014 - 2025)

Hosted

On-premise

Enterprise Size Outlook (Revenue, USD Billion, 2014 - 2025)

Large Enterprise

Small & Medium Enterprise (SME)

Country Outlook (Revenue, USD Billion, 2014 - 2025)

The U.S.

Canada

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."