Machine Tools Market Size, Share, & Trends Analysis Report By Type (Metal Cutting, Metal Forming), By Technology (CNC, Conventional), By End-use (Electrical Industry, Automotive), By Region, And Segment Forecasts, 2022 - 2030

- Report ID: GVR-4-68038-841-1

- Number of Pages: 120

- Format: Electronic (PDF)

- Historical Range: 2017 - 2020

- Industry:Advanced Materials

Report Overview

The global machine tools market size was valued at USD 77.22 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 5.7% over the forecast period. The primary reasons driving the industry include technological improvements in machine tools, such as robotic and multi-axis arms, as well as the growth in the manufacturing industry. The emergence of the COVID-19 pandemic has resulted in a global economic impact across all industry sectors in 2020. Machine tool manufacturers are also encountering issues as a result of this crisis, which has resulted in a slowdown in production and sales. Following the pandemic, growth will be supported by changing supply chain requirements and increased demand for digital services.

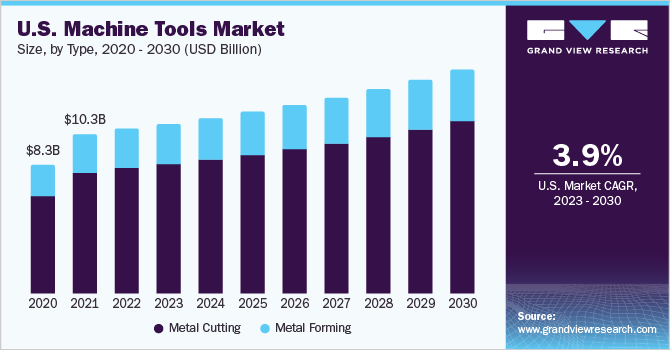

The industry in the U.S. is currently growing steadily. These products use numerical control, which aids in the production of uniform products. These tools aid in abrading, molding, grinding, sculpting, cutting, drilling, and nibbling metal or other hard materials. They also aid in reducing the amount of human labor necessary while cutting and increasing overall production. The defense, aerospace, and automobile sectors in the U.S. have been the primary drivers of demand for metal forming machine tools, as the need for fabricated metal products is significant in these industries. Thus, the expansion of the aforementioned industries is expected to drive product demand over the projection period.

的马rket is also driven by the rising demand for fabricated metals in the U.S and the high demand forElectric Vehicles(EVs),self-driving cars, and trucksare boosting the use of these products in the country. This, in turn, is anticipated to propel the product demand over the forecast period. The Industry 4.0 movement is gaining traction in the manufacturing sector, and it is also influencing the industry to become a component of smart systems. Industry 4.0 has the potential to enhance machine tool utilization in manufacturing operations by reducing idle time, which is likely to boost demand for these products over the forecast period.

Type Insights

The metal cutting type segment dominated the industry and accounted for the largest revenue share of more than 77.00% in 2021. Turning machine tools in the metal cutting segment accounted for a significant revenue share in 2021. The ability to turn machine tools to make a variety of items, such as airplane parts, electric motor parts, nuts, crankshafts, train components, pistons, wooden bowls, sleeves, bolts, pump parts, and others is expected to enhance their demand. Milling machining is a common production process used in machine shops and industries to create high-precision products and parts in a wide range of forms and sizes. The need for milling machines is predicted to increase due to benefits, such as reduced human errors, exact cuts, high precision, and the ability to make individual components in small or big batches.

The demand for metal forming machines is expected to witness growth at a considerable CAGR over the forecast period. Metal forming machines are used in a variety of industries including aerospace, automobile, appliance, energy, construction, metal building products, electronics, and others. Metal forming machine manufacturers include PMF Industries, Inc., Paramount Roll & Forming, Inc., Corrugated Metals, Inc., and others. Metal forming machines are used in a variety of procedures, including shearing, bending, pressing, shaping, and forming. The use of press brake machinery is expected to drive the segment. This is due to the widespread usage of press brake metal forming machines as a sheet bending tool in industries, such as agriculture, aerospace, shipbuilding, automotive, and petroleum machinery.

Technology Insights

The computerized numerical control machine segment accounted for the largest share of more than 85.75% of the global revenue in 2021. Factors, such as the increased need for higher efficiency and precision in complex machining products, as well as lower operating costs in industries, such as aerospace, automotive, and defense, have led to an increased usage ofCNC machines. CNC machines use an automated control system in which numerous components like sensors, controllers, and Programmable Logic Controller (PLC) drives are linked via a communication network. The increasing automation of manufacturing processes as a result of the rising need for higher precision and shorter lead times is likely to drive the industry over the forecast period.

CNC machine’s accuracy assures consistent product quality, resulting in higher production speed. The high demand for productivity increases from manufacturing organizations, combined with the growth of the industrial sector, has increased the demand, particularly for CNC machines. Low initial cost, ease of setup, and the flexibility to process various materials have contributed to an increased demand for traditional machines in bulk production industries, such as paper, textiles, and pharmaceuticals. A human operator is required to manage and steer machine tools, such as drilling, milling, and boring machines, lathes, and other sharp cutting tools, in traditional machines. Conventional machining is often less expensive and is utilized for smaller-volume tasks. However, a scarcity of competent workers is reducing the demand for traditional methods.

End-use Insights

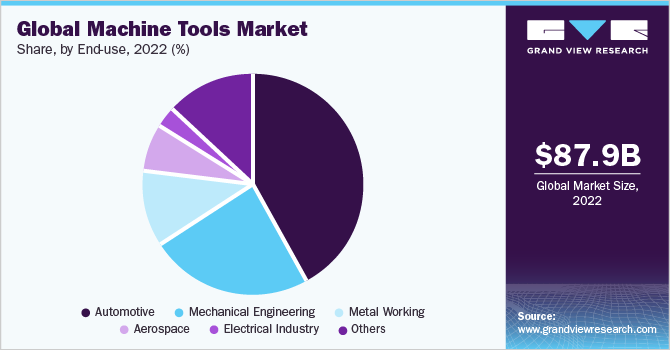

The automotive end-use segment dominated the industry and accounted for the maximum share of around 42.00% of the global revenue in 2021. The automotive segment is expanding as a result of the use of various machine tools used in the automobile industry. Milling machines are widely utilized in the automotive sector to produce parts, such as gearbox cases, engine locks, wheels, and piston rods. The aircraft sector is a major consumer of machine tool products. Continuous efforts are made in the aerospace sector to improve aircraft component production efficiency, increase flying safety, and reduce potential environmental damage.

The aerospace industry’s increased demand for advanced materials, such as nickel alloys and titanium alloys, is expected to stimulate the use of these products even more. Metalworking comprises manufacturing activities that generate industrial machinery and tools that supply parts to other connected industries, such as mining, agriculture, building, and others. The increasing utilization of these products in the metal working industry is expected to drive the segment growth over the forecast period. The extensive use of multi-axis systems by manufacturers of hydropower turbines and generators is also propelling the industry forward. Canyon Industries, Inc., for example, employs a 7-axis CNC milling machine capable of producing Francis and Pelton hydroelectric turbines with a diameter of 16 feet.

Regional Insights

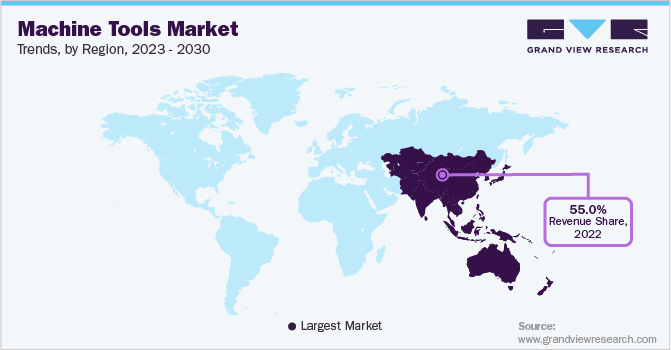

亚太地区占最大的share of more than 53.00% of the global revenue in 2021. The increasing need for these products in India in specific industries, such as construction, manufacturing, and automotive, is likely to drive the region’s growth. Government efforts that are being implemented are also boosting the region’s growth. This can be ascribed to efforts like “Make in India” that governments in the area are pursuing to stimulate the indigenous manufacturing industry. The product demand in the Asia Pacific is expected to rise as a result of the expanding manufacturing sector, particularly in the transportation, equipment, and other industries.

Machining centers are anticipated to contribute to the regional market growth over the projected period as a result of the ongoing trend toward higher-value goods. North America is also expected to grow at a significant CAGR during the forecast period owing to increased product demand in industries, such as aerospace & defense, automotive, and oil and energy. Electric car and van sales augmented dramatically in 2020, according to the European Environment Agency (EPA). Thus, increased investments in the EV sector are predicted to benefit the electric car market, thereby driving the product demand.

Key Companies & Market Share Insights

Manufacturers are undertaking several strategies including acquisitions, mergers, joint ventures, new product developments, and geographical expansions to enhance market penetration and cater to the changing technological requirements from various applications, such as automotive, metal working, electrical industry, aerospace, and others. The COVID-19 pandemic hampered the expansion of the industry. Product manufacturers suffered losses as a result of limited sales operations in several places across the world. The various degrees of lockdowns imposed internationally during the early stages of the pandemic hindered or temporarily stopped the movement of finished goods and raw materials, impacting the global manufacturing sector. Some of the prominent players in the global machine tools market include:

DMG MORI

CHIRON Group SE

Doosan Machine Tools Co., Ltd.

Georg Fischer Ltd.

Hyundai Wia Corp.

Okuma Corporation

JTEKT Corporation

Komatsu Ltd

Makino

Amera Seiki

Dalian Machine Tool Group (DMTG) Corp.

Datron AG

Haas Automation, Inc.

Hurco Companies, Inc.

Amada Co., Ltd.

Machine Tools Market Report Scope

Report Attribute |

Details |

Market size value in 2022 |

USD 81.5 billion |

Revenue forecast in 2030 |

USD 127.7 billion |

Growth rate |

CAGR of 5.7% from 2022 to 2030 |

Base year for estimation |

2021 |

Historical data |

2017 - 2020 |

Forecast period |

2022 - 2030 |

Quantitative units |

Revenue in USD million and CAGR from 2022 to 2030 |

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends |

Segments covered |

Type, technology, end-use, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country Scope |

U.S.; Canada; Mexico; Germany; France; Italy; Switzerland; Spain; China; Japan; India; South Korea; Taiwan; Brazil; Argentina; Saudi Arabia; South Africa |

关键的公司介绍 |

DMG MORI; CHIRON Group SE; Doosan Machine Tools Co., Ltd.; Georg Fischer Ltd.; Hyundai Wia Corp.; Okuma Corp.; JTEKT Corp.; Komatsu Ltd.; Makino; Amera Seiki; Dalian Machine Tool Group (DMTG) Corp.; Datron AG; Haas Automation, Inc.; Hurco Companies, Inc. |

Customization scope |

Free report customization (equivalent to up to 8 analysts' working days) with purchase. Addition or alteration to country, regional & segment scope |

定价和purchase options |

Avail of customized purchase options to meet your exact research needs.Explore purchase options |

Global Machine Tools Market Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global machine tools market report based on type, technology, end-use, and region:

Type Outlook (Revenue, USD Million; 2017 - 2030)

Metal Cutting

Machining Centers

Turning Machines

Grinding, Honing, Lapping Machines

Milling Machines

Eroding Machines (Laser, Electrical Discharge, Ultrasonic, etc.)

Others

Metal Forming

Presses

Bending, Folding, Straightening Machines

Punching Machines

Others

Technology Outlook (Revenue, USD Million; 2017 - 2030)

CNC

Conventional

End-use Outlook (Revenue, USD Million; 2017 - 2030)

Automotive

Mechanical Engineering

Metal Working

Aerospace

Electrical industry

Others

Regional Outlook (Revenue, USD Million; 2017 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

France

意大利

Switzerland

Spain

Asia Pacific

China

Japan

India

South Korea

Taiwan

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

South Africa

Frequently Asked Questions About This Report

b.The global machine tools market size was estimated at USD 77.2 Billion in 2021 and is expected to reach USD 81.5 Billion in 2022

b.的马chine tools market, in terms of revenue, is expected to grow at a compound annual growth rate of 5.7% from 2022 to 2030 to reach USD 127.7 Billion by 2030

b.Asia Pacific dominated the machine tools market with a revenue share of 6.7% in 2020. This is due to the increasing demand for machine tools with smart controls to enable autonomous operations, notably in the metal processing industry.

b.Some key players operating in the machine tools market include AMADA Co., Ltd.; CHIRON Group SE; DMG MORI; Doosan Corporation; Georg Fischer Ltd.; HYUNDAI WIA CORP.; JTEKT Corporation; Komatsu Ltd.; Makino; and Okuma Corporation.

b.Key drivers driving the machine tools market growth include rising need for improved productivity and downtime reduction, rising demand for lower operating costs, and rising demand from the automotive industry.