Injection Molding Market Size, Share & Trends Analysis Report By Material (Plastics, Metals), By Application (Packaging, Medical), By Region (North America, Europe, APAC, CSA, MEA), And Segment Forecasts, 2022 - 2030

- Report ID: GVR-4-68039-916-6

- Number of Pages: 152

- Format: Electronic (PDF)

- Historical Range: 2017 - 2020

- Industry:Advanced Materials

Report Overview

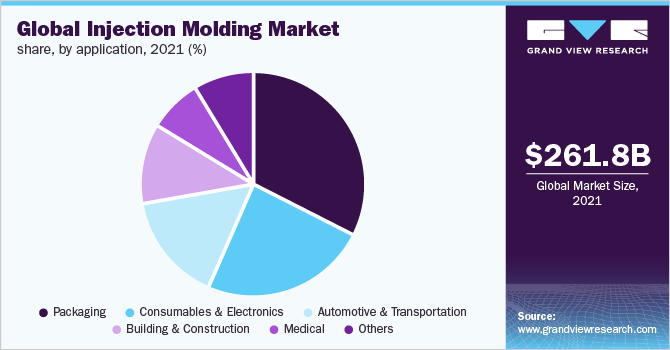

The global injection molding market size was estimated at USD 261.8 billion in 2021 and is anticipated to expand at a compounded annual growth rate (CAGR) of 4.8% from 2022 to 2030. The market growth is expected to be driven by the increasing demand for mass production of thousands of identical components at lower costs coupled with design flexibility, precision from various end-user industries such as packaging, medical, and electronics. The global economic recovery has been jolted by the quick emergence of the omicron strain in 2021. High transmissibility and ability to infect the vaccinated may lead to the imposition of lockdown and cause supply chain disruptions.

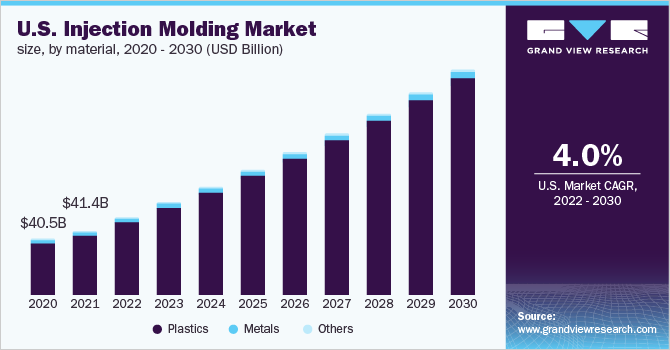

Furthermore, countries such as China, India, South Korea are focusing on strengthening domestic manufacturing to hedge themselves from future disruptions which are expected to boost the market demand. The injection molding market in the U.S. witnessed a transition due to the COVID-19 pandemic as the players are increasing capacity to meet the growing needs of the market. Factors such as the rising number of manufacturers using medical injection molding technology, increasing demand for medical equipment, and growing healthcare expenditure in the country are expected to positively affect the growth.

The three important steps in injection molding services consist of prototype making, bridge tooling, and mass manufacturing. Prototypes are vital for the development of parts as they allow the shape and form of these parts to be tested before moving forward to their production with the actual designs. Prototyping ensures the performance of parts is in line with their intended functions after mass manufacturing them without deviating from the set objectives. Bridge tooling is another step in the molding process that occurs between prototyping and production tooling. This stage can be used for the improvisation of parts that have been successful in their early testing phases.

工具适用于微调pro的桥梁cess, estimating project ROI, and testing before entering the market. The growing packaging and medical device industry is expected to drive growth. Manufacturing injection molded components by OEMs in-house can prove to be a significant challenge from efficiency, cost perspective, and quality. Many players are opting for outsourcing injection molding services as it offers strategic optimization, streamlined inventory, economies of scale, quick start-up time, improved quality among others.

Material Insights

The injection molding in plastics led the market and accounted for the largest revenue share of 98.3% in 2021 owing to low-cost technology suitable for high-volume production runs and applications that require consistency in design and strict tolerances thatplasticoffers. Recent innovations to minimize the rate of faulty production have encouraged mass production of complicated plastic shapes, especially in packaging, consumer goods, and construction augmenting the industry growth. The demand forplastic resinsin injection molding is witnessing increased adoption due to factors such as high tensile strength, increased metal tolerance, and high-temperature endurance. Moreover, these resins enable a reduction in manufacturing waste, product weight, and overall manufacturing costs, thereby augmenting industry growth.

The metal material segment is likely to witness a CAGR of 7.3% over the forecast period. Factors such as resistance to corrosion, superior surface finish, and ability to manufacture parts with complex geometries have resulted in demand for metal molded components. Furthermore, increasing demand for minimally invasive surgeries has led to the surged demand for metal medical injection molded components. The rising costs of recyclability of plastics have led manufacturers to switch towards bioplastics that have similar properties to plastics and are environmentally friendly. Furthermore, the rising demand for rubber and ceramics products in medical, automotive, and electronics end-use industries is anticipated to have a positive impact on industrial growth.

Application Insights

包装应用程序段led产业y and accounted for the largest revenue share of 32.4%. The increased demand for injection molding in packaging is attributed to the changing consumer trends, sustainability, ande-commercepenetration. Furthermore, increasing investments in food processing, pharmaceutical, and personal care industries are boosting the service demand for packaging products. The growth in smartphone,artificial intelligence, and voice recognition technologies coupled with the presence of technology-driven companies is expected to play a key role in the injection molding market growth. Rising demand for connectors, plug connectors, and sensors, as well as electronic components and other electronics, is expected to drive the growth.

The medical application segment is likely to witness a CAGR of 5.7% over the forecast period. In the wake of the COVID-19 pandemic, the demand for medical devices and components increased considerably. Ongoing advancements in the field of surgery in the form of standardization of methods and technological progressions are anticipated to drive the expansion of the medical sector and fuel the demand for injection molded medical components. The advent ofelectric vehiclesglobally has provided an opportunity for injection molding service providers in automobile applications. Brakes, clutching system, and drive trains, consists of components such as gears, seals, and magnets, manufactured using injection molding. Moreover, the growing demand for replacing metal components with plastic in automobiles is expected to drive during the forecast period.

Regional Insights

Asia Pacific led the market and accounted for the largest revenue share of 40.4% in 2021. A favorable environment for industrial growth, abundant raw materials, low-cost labor coupled with increasing investments in the packaging, medical, and electronics applications are expected to boost the demand for these products over the forecast period. In North America, rising healthcare expenditure and the increasing elderly population are anticipated to have a positive impact on the growth of the medical sector. The ongoing spread of the omicron variant of COVID-19 in North America has increased hospitalization, thereby fueling the demand for medical injection molding services. Furthermore, rapid innovation in the packaging and automobile sector is anticipated to boost the market growth.

In Central and South America, the market is likely to witness a CAGR of 5.1% over the forecast period owing to growing investments in disruptive technologies, such as robotics, artificial intelligence,IoT, and cloud technologies required molded components. These factors coupled with increased private consumption and the growth in the healthcare industry are expected to drive the market in the region. Europe accounted for a significant share of global revenue in 2021, owing to innovation, growing investment stimulus, and technology promotion in various end-use sectors such as packaging, automobile, and medical. Growing demand for sustainable, recyclable, smart packaging from various end-users is expected to impact the growth positively.

Key Companies & Market Share Insights

The market is highly competitive with companies focusing on acquisitions to acquire the market share and also increase capacity to meet the growing demand from various end-user industries. Furthermore, the companies have realized the importance of forward integration as several companies are utilizing their cash flows during the pandemic to acquire these product suppliers. The sales channel for injection molding is undergoing a transition during the pandemic with manufacturers strengthening their online sales channel. Service providers are deploying web content to target specific end-user industries in order to create a niche for themselves. Companies are also incorporating industry 4.0 in their manufacturing process to increase profits and streamline processes. Some of the prominent players in the injection molding market include:

C&J INDUSTRIES

All-Plastics

Biomerics

HTI Plastics

The Rodon Group

EVCO Plastics

Majors Plastics, Inc.

Proto Labs, Inc.

Tessy Plastics

Currier Plastics, Inc.

Formplast GmbH

H&K Müller GmbH & Co. KG

Hehnke GmbH & Co KG

TR PLAST GROUP

D&M Plastics, LLC

Injection Molding Market Report Scope

Report Attribute |

Details |

Market size value in 2022 |

USD 273.2 billion |

Revenue forecast in 2030 |

USD 397.6 billion |

Growth Rate |

CAGR of 4.8 % from 2022 to 2030 |

Base year for estimation |

2021 |

Historical data |

2017 - 2020 |

Forecast period |

2022 - 2030 |

Quantitative units |

Revenue in USD million and CAGR from 2022 to 2030 |

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends |

Segments covered |

Material, application, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country Scope |

U.S.; Canada; Mexico; Germany; France; U.K.; Spain; Italy; China; India; Japan; South Korea; Australia; Brazil; Argentina; Saudi Arabia; UAE |

Key companies profiled |

C&J INDUSTRIES; All-Plastics; Biomerics; HTI Plastics; The Rodon Group; EVCO Plastics; Majors Plastics, Inc.; Proto Labs, Inc.; Tessy Plastics; Currier Plastics, Inc.; Formplast GmbH; H&K Müller GmbH & Co. KG; Hehnke GmbH & Co KG; TR PLAST GROUP; D&M Plastics, LLC |

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional, and segment scope. |

定价和purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Segments Covered in the Report

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For the purpose of this study, Grand View Research has segmented the global injection molding market report on the basis of material, application, and region:

Material Outlook (Revenue, USD Million, 2017 - 2030)

Plastics

Metals

Others

Application Outlook (Revenue, USD Million, 2017 - 2030)

Packaging

Consumables & Electronics

Automotive & Transportation

Building & Construction

Medical

Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

France

Italy

U.K.

Spain

Asia Pacific

China

India

Japan

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

Frequently Asked Questions About This Report

b.The global injection molding market size was estimated at USD 261.8 billion in 2021 and is expected to reach USD 273.2 billion in 2022

b.The injection molding market is expected to grow at a compound annual growth rate of 4.8% from 2022 to 2030 to reach USD 397.6 billion by 2030

b.The Asia Pacific dominated the injection molding market with a share of 40.4% in 2021, owing to the growing industrialization, availability of raw labor, raw materials, and increasing investments in the packaging, electronics coupled with a strong consumer base in the region

b.Some of the key players operating in the injection molding market include C&J INDUSTRIES, All-Plastics, Biomerics, HTI Plastics, The Rodon Group, EVCO Plastics, Majors Plastics, Inc, Proto Labs, Inc, Currier Plastics, Inc., Formplast GmbH, H&K Müller GmbH & Co. KG, Hehnke GmbH & Co KG, TR PLAST GROUP, D&M Plastics, LLC. among others

b.推动注射摩尔的关键因素ding market include increasing demand for mass production of components coupled with rising demand for injection molding services from application industries such as packaging, electronics, and medical