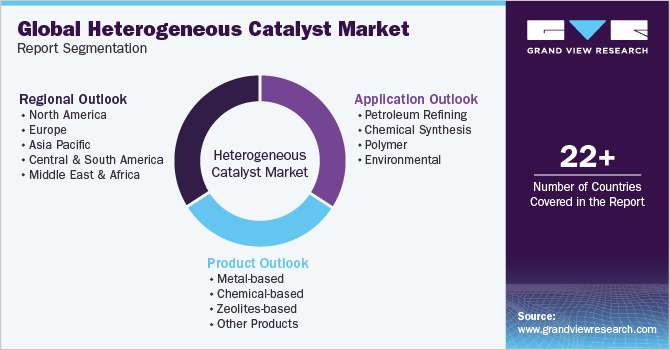

Heterogeneous Catalyst Market Size, Share & Trends Analysis Report By Product (Metal -based, Chemical-based, Zeolites-based), By Application (Petroleum Refining, Chemical Synthesis, Polymer), By Region, And Segment Forecasts, 2023 - 2030

- Report ID: GVR-4-68040-125-8

- Number of Pages: 80

- Format: Electronic (PDF)

- Historical Range: 2018 - 2021

- Industry:Specialty & Chemicals

ReportOverview

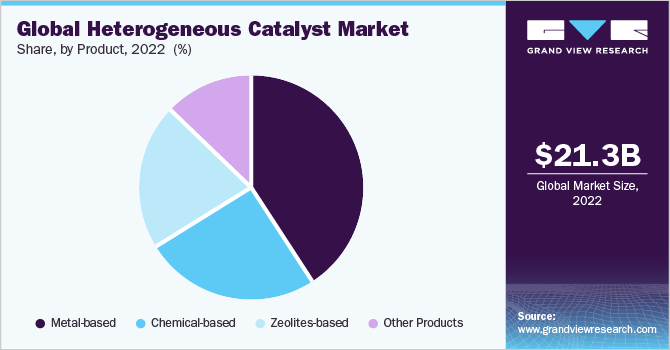

The globalheterogeneous catalyst market sizewas valued atUSD 21.3 billion in 2022预计到年复合增长增长th rate (CAGR) of 4.5% from 2023 to 2030. The heterogeneous catalysts are widely used in industrial processes such as oil refining, chemical synthesis, and energy production. The growth of these industries, along with the need for more efficient and sustainable processes, increases the demand for market.

Heterogeneous catalysts are solid materials that promote chemical reactions by offering an active surface for reactant molecules to adsorb, undergo reactions, and subsequently desorb as products. These substances find widespread application across various industrial domains, encompassing petroleum refining, petrochemicals, pharmaceuticals, food processing, polymers, and environmental preservation.

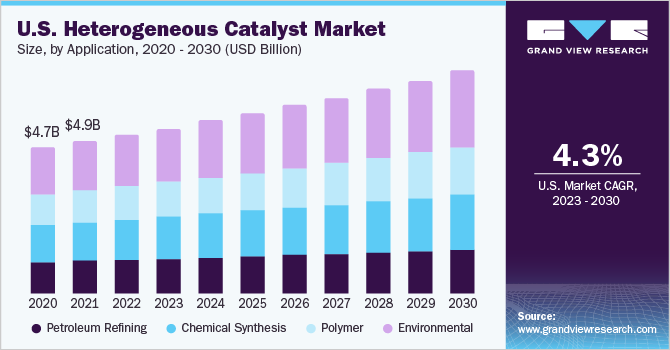

The U.S. is a major player in the petroleum refining industry, and heterogeneous catalysts are extensively used to improve the efficiency and yield of refining processes. Product such as zeolites, which are composed of alumina and silica, find applications in catalytic cracking, isomerization, and reforming processes.

These products help convert heavy crude oil fractions into valuable gasoline, diesel, and other refined products, ensuring optimal utilization of domestic crude oil resources. Chemical synthesis in the U.S. extensively relies on heterogeneous catalysts to produce various chemicals and intermediates. Metal-based products, including platinum, palladium, and nickel, are widely used in hydrogenation, oxidation, and hydrogenolysis reactions.

The U.S. emphasis on environmental protection, and heterogeneous catalysts are instrumental in this effort by facilitating pollution treatment and remediation. The United States relies on heterogeneous catalysts in various sectors, including petroleum refining, chemical synthesis, polymers, and environmental protection. These enable crucial reactions, enhancing efficiency, selectivity, and sustainability in industrial processes.

Product Insights

The metal-based product segment dominated the market with a revenue share of 41.0% in 2022. This is attributable to the fact that metal-based catalysts, such as platinum, palladium, and rhodium, are widely used in industries such as petroleum refining, petrochemicals, and automotive manufacturing. These products enable essential processes like catalytic cracking and hydrotreating in the petroleum refining sector, facilitating the conversion of crude oil into valuable fuels and related products. Metal-based substances are also integral to catalytic converters, reducing harmful emissions from vehicles and promoting environmental sustainability.

Chemical-based products, which include acids, bases, and complex organic compounds, are in high demand across various sectors, including pharmaceuticals, polymers, and specialty chemical manufacturing. Chemical-based products offer the advantage of tailoring reaction conditions, making them indispensable in the pharmaceutical industry, particularly in chiral synthesis, where they are used to produce enantiopure compounds. They also contribute significantly to the production of polymers, resins, and specialty chemicals, driving advancements in materials science and enhancing overall product performance.

Zeolites, characterized by their crystalline aluminosilicate structure and regular pore arrangements, have gained prominence as heterogeneous catalysts. Zeolite-based catalysts find extensive applications in the petroleum and petrochemical industries, providing high selectivity and stability in processes such as catalytic cracking, isomerization, and alkylation. Additionally, zeolites are utilized in natural gas purification and detergent production, effectively contributing to sustainable and efficient manufacturing processes.

Application Insights

The environmental application segment dominated the market with a revenue share of 32.0% in 2022. This growth is attributed to the heterogeneous catalysts playing a significant role in environmental applications, particularly in processes aimed at mitigating pollution and reducing harmful emissions. Catalytic converters in vehicles utilize metal-based catalysts, such as platinum and rhodium, to catalyze the conversion of harmful gases like carbon monoxide, nitrogen oxides, and volatile organic compounds into less harmful substances. These catalysts help reduce air pollution and improve air quality, making them crucial in achieving sustainable transportation.

In the petroleum refining industry, heterogeneous catalysts are instrumental in the conversion of crude oil into valuable products such as gasoline, diesel, and jet fuel. Catalytic processes like catalytic cracking, hydrocracking, and hydrotreating are employed to break down complex hydrocarbon molecules, remove impurities, and enhance product quality. Metal-based catalysts, such as platinum or palladium, are often used in these refinery processes to increase reaction rates and improve selectivity, leading to higher yields and better product specifications. These catalysts play a critical role in ensuring the availability of clean, high-quality fuels that meet ever-tightening environmental regulations.

Chemical synthesis heavily relies on heterogeneous catalysts to produce various chemicals used in pharmaceuticals, specialty chemicals, and many other industrial sectors. Chemical-based catalysts, such as acids, bases, and complex organic compounds, are employed to promote specific reactions and drive the synthesis of desired compounds. For example, in the pharmaceutical industry, heterogeneous catalysts enable the creation of intricate and highly pure molecules, supporting the development of life-saving drugs. Similarly, in specialty chemical manufacturing, these product facilitate the production of tailored compounds with unique properties and functionalities.

Polymer production involves the use of market to initiate and control polymerization reactions, leading to the formation of polymers with specific structures and properties. Ziegler-Natta catalysts, based on transition metals like titanium or chromium, are extensively used in the production of polyethylene and polypropylene, the most widely used plastic materials worldwide. Heterogeneous catalysts enable the synthesis of polymers with desired molecular weights, distributions, and stereochemistry, contributing to the versatility and performance of these materials in various applications.

Regional Insights

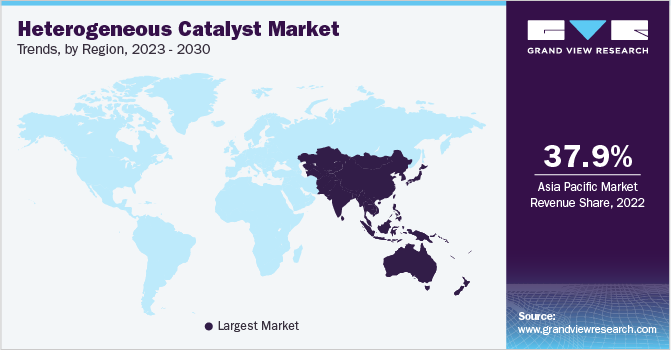

Asia Pacific dominated the market with a revenue share of 37.9% in 2022. This is attributable to the escalating demand for products in the leading nations, namely China and India. In these countries, the extensive agricultural sector catering to their vast population necessitates significant enhancement in food production. China's demand for market is primarily attributed to the cultivation of crops such as rice, wheat, corn, and vegetables.

Europe is another important market for heterogeneous catalysts. The region is home to several established chemical and automotive industries that rely on catalysts for various processes. European countries like Germany, France, and the UK have a strong research and development culture, leading to the development of innovative catalyst technologies. Sustainability initiatives and stringent regulations also drive the market as Europe aims to reduce emissions and promote cleaner industrial processes.

North America, including the U.S. and Canada, is a prominent market for heterogeneous catalysts. The region's mature industrial base, particularly in sectors like petroleum refining, petrochemicals, and chemicals, drives the demand for catalysts. Additionally, North America has a strong focus on research and development, leading to the continuous development of advanced catalyst technologies. Stringent environmental regulations also require the use of catalysts to control emissions, supporting market growth.

Key Companies & Market Share Insights

The market is highly competitive in nature. Key players penetrating the regions are involved in broadening their product portfolio and global presence. These manufacturing companies undertake various partnerships and distribution agreements to meet the rising demand for the product in new geographical markets.

Players are entering into mergers and partnerships to establish their position in the market. For instance, W. R. Grace & Co.-Conn. announced the completion of its acquisition of Rive Technology, Inc., an FCC catalysts manufacturer. The acquisition included all the service offerings, employees, and technological assets, which were integrated into W.R Grace & Co. - Conn’s business model. This integration of technology allowed a better customer-centric product range to meet the growing catalyst demands from petrochemical and refining sectors. Some of the prominent players in the global Heterogeneous catalyst market include:

Albemarle Corporation

Haldor Topsoe A/S

BASF SE

Evonik Industries AG

Rio Tinto Ltd.

LyondellBasell Industries Holdings B.V.

Arkema

The Dow Chemical Company

Haldor Topsoe A/S

W. R. Grace & Co.-Conn.

Johnson Matthey

Axens

Honeywell UOP

Zeolyst International

Clariant

Umicore

Exxon Mobil Corporation

Heterogeneous Catalyst Market Report Scope

Report Attribute |

Details |

Market size value in 2023 |

USD 22.25 billion |

Revenue forecast in 2030 |

USD 30.2 billion |

Growth rate |

CAGR of 4.5% from 2023 to 2030 |

Base year for estimation |

2022 |

Historical data |

2018 - 2021 |

Forecast period |

2023 - 2030 |

Quantitative units |

Volume in kilotons, revenue in USD million/billion, and CAGR from 2023 to 2030 |

Report coverage |

Volume & revenue forecast, company ranking, competitive landscape, growth factors, and trends |

Segments covered |

Product, application, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country scope |

U.S.; Canada; Mexico; Germany; U.K.; France; Italy; Spain; Russia; The Netherlands; China; India; Japan; South Korea; Malaysia; Indonesia; Australia; Brazil; Saudi Arabia; South Africa |

Key companies profiled |

Albemarle Corporation; BASF SE; Evonik Industries AG; LyondellBasell Industries Holdings B.V.; Arkema; W. R. Grace & Co.-Conn.; W. R. Grace & Co.-Conn.; Johnson Matthey Plc; Axens SA; Clariant International Ltd.; ExxonMobil Corporation; Umicore |

Customization scope |

免费定制(相当于8肛交报告ysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Global Heterogeneous Catalyst Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global Heterogeneous catalyst market report on the basis of product, application, and region:

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Metal-based

Chemical-based

Zeolites-based

Other Products

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Petroleum Refining

Chemical Synthesis

Polymer

Environmental

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

U.K.

France

Italy

Spain

The Netherlands

Russia

Asia Pacific

China

India

Japan

South Korea

Malaysia

Australia

Indonesia

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

South Africa

Frequently Asked Questions About This Report

b.The global heterogeneous catalyst market size was estimated at USD 21.3 billion in 2022 and is expected to reach USD 22.25 billion in 2023.

b.The global heterogeneous catalyst market is expected to grow at a compound annual growth rate of 4.5% from 2023 to 2030 to reach USD 30.2 billion by 2030.

b.Asia Pacific dominated the heterogeneous catalyst market with a revenue share of 35% in 2022. This is attributable to the escalating demand for products in the leading nations, namely China and India.

b.Some key players operating in the heterogeneous catalyst market include Albemarle Corporation; BASF SE; Evonik Industries AG; LyondellBasell Industries Holdings B.V.; Arkema; W. R. Grace & Co.-Conn.; W. R. Grace & Co.-Conn.; Johnson Matthey Plc; Axens SA; Clariant International Ltd.; ExxonMobil Corporation; Umicore

b.Key factors driving the market growth include the increasing growth of oil refining, chemical synthesis, and energy production industries, along with the need for more efficient and sustainable processes, increasing the demand for the market.