Glass Lined Equipment Market Size, Share & Trends Analysis Report By Product (Reactors, Agitators, Heat Exchangers), By End-use (Pharmaceutical, Chemicals, Agriculture), By Region, And Segment Forecasts, 2023 - 2030

- Report ID: GVR-4-68040-142-3

- Number of Pages: 169

- Format: Electronic (PDF)

- Historical Range: 2018 - 2021

- Industry:Bulk Chemicals

Glass Lined Equipment Market Trends

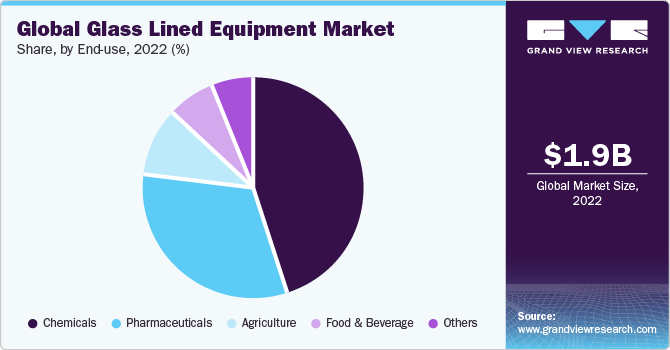

The globalglass lined equipment market size was estimated at USD 1.92 billion in 2022and is anticipated to grow at a compound annual growth rate (CAGR) of 10.2% from 2023 to 2030. The market is primarily driven by its exceptional corrosion resistance and durability, making it a preferred choice in industries such as pharmaceuticals, chemicals, and food processing. The inert nature of glass lining ensures product purity, crucial for industries with stringent quality standards. The increasing focus on environmental sustainability has propelled the demand for glass lined equipment, as it is a recyclable and eco-friendly alternative. Stringent regulatory standards regarding product safety and hygiene further contribute to the market growth. The rising investments in infrastructure development and the expansion of manufacturing facilities also play a significant role in the market's growth.

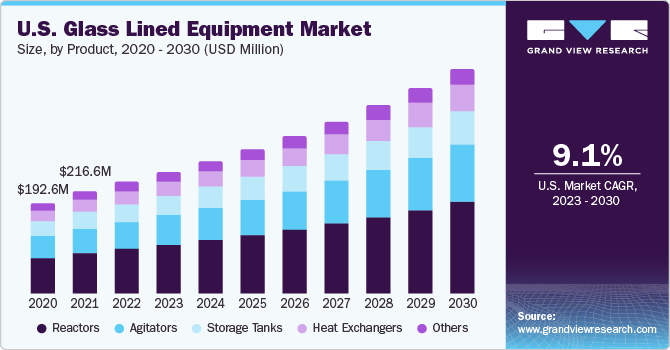

The U.S. glass lined equipment market’s growth is fueled by technological advancements and innovation in manufacturing processes. Continuous R&D efforts are leading to the creation of advanced glass coatings with enhanced properties, further broadening the applications of these equipment across various industries. The pharmaceutical andbiotechnologysectors are also witnessing significant growth in the U.S. This surge in pharmaceutical activities directly boosts the demand for glass lined vessels, which are crucial for processes requiring a high level of purity and corrosion resistance.

According to ‘Pharma’, the pharmaceutical industry is predicted to reach USD 1,494 billion by 2023. According to the United Nations World Population Prospects, the global population is predicted to reach 9.3 billion by 2050, with approximately 21% of this population falling in the age group of 60 years and above. Moreover, the increase in purchasing power of the masses and their access to quality healthcare facilities and pharmaceuticals worldwide are fueling the growth of the global pharmaceutical industry. This, in turn, is anticipated to contribute to the surged adoption of glass lined equipment in the pharmaceutical industry over the forecast period.

Furthermore, the页岩气gydF4y2Baboom in the U.S. has propelled growth in the chemical and petrochemical industries. Glass lined equipment's resistance to harsh chemicals and its ability to withstand high temperatures make it indispensable in these sectors. The growing popularity of specialty chemicals and the need for reliable equipment in the production processes contribute to the market's upward trajectory. The glass lined reactor is crucial to the chemical process in which chemical reactions occur. In numerous industries, including chemical, polymer, dye & pigment, color, and pharmaceutical, the role of a reactor is crucial. The rising need for high-performance and function-specific chemicals in end-use sectors, such as oil & gas, pulp & paper, and personal care & cosmetics, is anticipated to be one of the most important market drivers.

End-use Insights

化学物质部分领导市场,占据for 45.3% of the global market share in 2022. Glass-lined agitators are essential from crude oil storage tanks to the refining and processing phases in the petrochemical industry. In crude oil storage tanks, the deposition of sludge, which is composed of both inorganic and organic materials, must be agitated to ensure off-bottom suspension. This lowers the difficulty of the downstream process and prevents settling in the tank, which may affect the tank's capacity and the agitator's performance.

Heat exchangers are used in a wide range of agricultural applications. They are often used to keep hugeagricultural equipmentand machinery, especially automated equipment, from overheating. Some organizations use heat exchangers to maintain livestock quarters at reasonable temperatures to prevent inhumane situations or a decline in cattle quality. Even the manufacturing of biofuels, a crucial aspect of many agricultural activities, can be made safer and more effective with the use of the appropriate heat exchanger technology.

The pharmaceuticals segment is anticipated to witness a CAGR of 10.8% over the forecast period. Various types of glass lined equipment are utilized in the pharmaceutical manufacturing industry. The functions and applications of a pharmaceutical department are to determine the criteria for selecting glass lined equipment for vessels. In the pharmaceutical industry, some departments use these equipment as their primary vessel, for instance, the injectable department, where the use of conventional equipment is not feasible.

Glass lined equipment is also utilized in industries that deal with chemically active substances for process operations in the petrochemical, food, and pesticide industries. To prevent contamination, the food industry uses hygienically engineered equipment throughout the production line. During batch processing, the equipment must be able to endure both high-temperature cooking and steam cleaning. Large glass-lined agitators are frequently used to combine substances, and the glass lined equipment provide a cost-effective alternative to stainless steel.

Product Insights

Based on product, the reactors segment led the market of glass lined equipment and accounted for 39.9% of the global market share in 2022. Reactors are a crucial component of production lines in modern process plants, and they are widely employed in industries such as medicines,petrochemicals, pesticides, light industries, food, dyes, and scientific research. In chemical and pharmaceutical industries, glass lined reactors are used owing to their chemical compatibility.

The agitators segment is expected to witness a CAGR of 10.9% over the forecast period. The increasing demand for glass-lined agitators is primarily driven by their pivotal role in enhancing mixing efficiency and optimizing chemical processes across industries such as pharmaceuticals, chemicals, and food processing. These agitators offer a corrosion-resistant and inert solution crucial for maintaining product purity and quality in aggressive chemical environments. As industries strive for operational excellence and adherence to stringent quality standards, the reliability and durability of these agitators become indispensable, making them a key enabler for efficient mixing, reaction control, and overall process optimization.

Storage tanks are utilized to contain raw materials for final products after treatment in glass-lined reactors, food goods (fruit juices, milk, etc.), and medications that require strict purity and non-contamination standards. Atmospheric or pressurized storage is available. Glass-lined storage tanks are appropriate for chemically aggressive, extremely corrosive, and generally hazardous compounds, such as oxidizing, acidic, & reducing agents, metal-sensitive products, bromine, and chlorine, to preserve purity, color, flavor, and odor. In addition, these tanks are well-suited for sticky adhesive liquids that tend to produce encrustations.

Regional Insights

Asia Pacific region dominated the market in 2022, accounting for a market share of 39.5%. The pharmaceutical industry in China, Japan, and India is anticipated to experience significant growth in the coming years owing to the continuous increase in the aging population of these countries. This is anticipated to lead pharmaceutical companies to invest in the region. All these factors are expected to increase the adoption of technologically advanced processes in the region and stimulate the expansion of the market.

The food & beverage industry in Central & South America has experienced a tremendous expansion in recent years as a result of industrial sector investments. Rapid urbanization in nations such as Argentina, Brazil, and Chile contributes to the expansion of this industry. The rising demand for novel flavors and cuisines in the food & beverage industry is expected to have a beneficial effect on the market expansion. In addition, the COVID-19 pandemic has resulted in a change in consumer behavior, which has prompted food & beverage product makers to introduce new items, particularly in the alcoholic beverages market. The food and beverage industry has moved away from imitation toward innovation. Glass lined equipment plays a vital role in protecting the freshness of food & beverage products, and extending their shelf life.

欧洲地区预计将见证CAGR为9.5% over the forecast period. The pharmaceutical market in Europe is predicted to expand at a rapid rate in future years. This is attributed to the escalating cost of healthcare, the development of biosimilar and biologics, and rising investment in various R&D endeavors. In addition, a supportive regulatory framework and reimbursement policies stimulate the uptake of medications in the European pharmaceutical market.

Large petrochemical projects, including the Petro Rabigh refinery, the Ras Tanura refinery, and the Jizan export refinery, have been funded by Middle-Eastern nations, including Saudi Arabia, the UAE, and Kuwait. In this sector, glass-lined agitators are indispensable, from crudeoil storagetanks to the refining and processing phases. Chemical and petrochemical production is projected to increase to meet the rising demand from end-use industries such as pharmaceutical, and chemical. The expanding chemical sector in the region is anticipated to increase the demand for glass lined equipment over the forecast period.

Key Companies & Market Share Insights

To increase market penetration and meet changing technical demands, key manufacturers employ a variety of methods such as geographical expansions, product launches, and mergers and acquisitions. For instance, in May 2022, GMM Pfaudler expanded its glass lined equipment manufacturing facility in India. Furthermore, the company invested USD 3.7 million to increase its production capacity.

Glass Lined Equipment Companies:

- GMM Pfaudler

- Büchiglasuster

- SGT Glass-Lined Equipment Co., Ltd

- HLE Glascoat

- THALETEC

- 3V Tech S.p.A.

- Standard Group of Companies Ltd

- Zibo Taiji Industrial Enamel Co., Ltd

- Jiangsu Yangyang Chemical Equipments Manufacture Co., Ltd

- SACHIN INDUSTRIES LTD.

Glass Lined Equipment Market Report Scope

Report Attribute |

Details |

Market size value in 2023 |

USD 2.10 billion |

Revenue forecast in 2030 |

USD 4.14 billion |

Growth rate |

CAGR of 10.2 from 2023 to 2030 |

Base year for estimation |

2022 |

Historical data |

2018 - 2021 |

Forecast period |

2023 - 2030 |

Quantitative units |

Revenue in USD million/billion and CAGR from 2023 to 2030 |

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, trends |

Segments covered |

Product, end-use, region |

Regional scope |

北美;欧洲;亚太地区;中东&Africa; Central & South America |

Country scope |

U.S.; Canada; Mexico; Germany; France; Italy; UK; Spain; China; India; Japan; South Korea; Australia; Brazil; Argentina; Saudi Arabia; South Africa |

Key companies profiled |

GMM Pfaudler; Büchiglasuster; SGT Glass-Lined Equipment Co., Ltd; HLE Glascoat; THALETEC; 3V Tech S.p.A.; Standard Group of Companies Ltd.; Zibo Taiji Industrial Enamel Co., Ltd; Jiangsu Yangyang Chemical Equipments Manufacture Co., Ltd.; SACHIN INDUSTRIES LTD |

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Global Glass Lined Equipment Market Report Segmentation

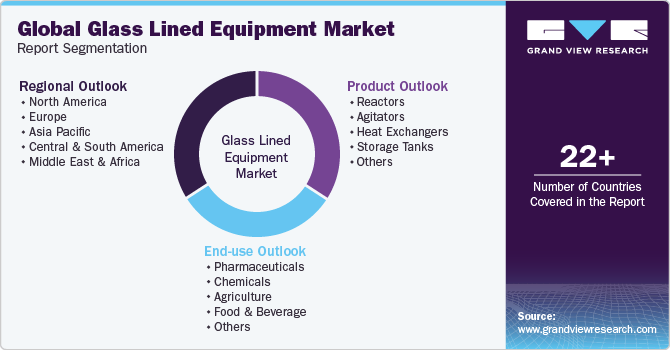

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global glass lined equipment market report based on product, end-use, and region:

Product Outlook (Revenue, USD Million, 2018 - 2030)

Reactors

Agitators

Heat Exchangers

Storage Tanks

Others

End-use Outlook (Revenue, USD Million, 2018 - 2030)

Pharmaceuticals

Chemicals

Agriculture

Food & Beverage

Others

Region Outlook (Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

Japan

Australia

India

South Korea

Central & South America

Brazil

Argentina

中东&Africa

Saudi Arabia

South Africa

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."