Europe MRO Distribution Market Size, Share & Trends Analysis Report By Distribution Channel (Direct, Indirect), By Maintenance Type, By Sourcing/Service Type, By Product, By Application, And Segment Forecasts, 2022 - 2030

- Report ID: GVR-1-68038-886-2

- Number of Pages: 193

- Format: Electronic (PDF)

- Historical Range: 2017 - 2020

- Industry:Advanced Materials

Report Overview

The Europe MRO distribution market size was estimated at USD 202.88 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 2.8% from 2022 to 2030. Growing demand for repair, maintenance, and service operations in manufacturing and industrial activities majorly in Norway, Sweden, Germany, and Finland is expected to provide growth opportunities to the maintenance, repair, & overhaul (MRO) market. Commercial availability of the MRO products and skilled workforce for services has created a wide scope for the development of industrial and manufacturing activities in the region. This also has improved sales for the prominent players in European economies. Furthermore, ascending industrial output is expected to increase the MRO operations in Germany, Italy, France, and Russia.

Several industries in Europe have adopted integrated service concepts to improvise the quality of service and equipment that are used in critical operations. This concept also helps the industries to reduce the cost of repair and maintenance. This trend is anticipated to drive the market in Europe over the projected time. As maintenance and repair operations are an integral part of daily operational activities and the elevation of the MRO distribution industry in the region, especially post-recession period along with the advantages associated with the outsourcing of MRO processes, most industries in Europe prefer to be associated with distributors rather than managing these activities in-house. These factors are expected to drive the market in Europe over the forecast period.

The introduction ofe-commerce平台有显著影响的区域market. Distributors and the channel partners for the essential components of MRO have benefitted themselves through these platforms owing to a more optimized and smooth operational flow. This has directly influenced the business models for MRO service providers across Europe. Key players are focusing on achieving optimal operational costs, enhancing the quality, maximizing output, and acquisition of small players to sustain themselves in the competitive market. Along with the component distribution, major players are focusing on providing additional services for repair and maintenance. Also, these players are focusing on inventory management to smoothen the in-flow and out-flow of the components.

Product Insights

The machine consumables segment led the market in 2021 and accounted for a revenue share of more than 30%. Worn-out machine parts and exceeding the machine capacity are the factors for replacement and repair of machine consumables over time. These consumables include wires, machine oils, fluids, rotators, shafts, general machine spare parts, cutting devices, and fasteners among others. Rising demand for durable and sophisticated bearings is anticipated to drive this product segment over the forecast period. The demand forbearingsin the automotive and machinery manufacturing industries can be attributed to their efficiency in carrying high loads and the requirement of low maintenance.

Cast iron,stainless steel, copper, special alloys,carbon steel, and thermoplastics are the major raw materials used for producing pipes, valves, and fittings. As these products are used for supplying highly intensive oils and gases, MRO operations are carried out at regular intervals and thus are influencing the distribution of pipes, valves, and fittings. Lights, wires, and cables need periodic replacement and maintenance owing to their short lifespan as compared to other electrical items. Moreover,appliances, sockets, and switchgear require maintenance at frequent intervals. MRO operations about this product segment also focus on electric circuits installed in building structures as the circuits are prominently responsible for the inflow and stability of the electric current to machinery and equipment.

Sourcing/Service Type

外部MRO分布操作段led the market in 2021 and accounted for a revenue share of more than 71%. A majority of the companies are focusing on reducing the efforts of their internal departments about MRO operations. Instead, the task of these operations is assigned to external service providers with a skilled workforce. External MRO service providers in Europe are focusing on providing precise solutions for advanced technology machinery. Benefits, such as maintenance at regular intervals, technical know-how about the machinery, and knowledge about the repair & maintenance of complex equipment, are the factors contributing to the rising popularity of external MRO service providers.

Internal MRO operations are carried out within the manufacturing facilities to ensure a smooth flow of operations. MRO services are majorly used to avoid interruptions caused by unexpected issues that occur during production. The management carries out these operations for immediate repair and maintenance in case of machine breakdown due to some fault. Lower cost of operations and excellent inventory control are some of the benefits associated with internal MRO management. The dedicated department in the company for MRO-related operations is responsible for product supply to the manufacturing facilities. This can reduce the turnaround time to fix an issue in the operational units.

Maintenance Type Insights

The preventive/scheduled maintenance operation segment accounted for the largest revenue share of over 58%. This type of maintenance is performed on particular machinery to reduce the chances of its failure. Protecting the machinery or equipment from unexpected breakdowns and ensuring a smooth flow of operations are factors boosting the need for scheduled maintenance among companies. Preventive maintenance is planned by companies to establish consistent practice cycles for performance improvement and to enhance the safety of the equipment. Furthermore, planned maintenance helps decrease downtime and reduce the number of repairs for a particular machine. The increased life expectancy of the machine, better conservation of assets, and reduced overtime cost are several other factors for the popularity of preventive/scheduled maintenance.

Corrective maintenance is carried out at production facilities to resolve a breakdown and/or faults that have occurred in operations. These maintenance activities are majorly carried out when an issue is sensed in the conditional monitoring when there is a potential fault in routine inspection, and in case of equipment breakdown. The two types of corrective maintenance activities include planned and unplanned corrective maintenance. MRO service providers are engaged in offering corrective maintenance services to the production facilities by conducting a regular check on the machinery and tools. In addition, routine inspection is carried out in the units to monitor the efficiency of the working components in the machinery.

Distribution Channel Insights

The direct distribution channel segment led the market in 2021 and accounted for a revenue share of more than 70%. The segment is projected to grow at a steady CAGR from 2022 to 2030. Lower cost and bulk delivery of the components used in MRO operations are anticipated to further drive the direct supply segment over the coming years. Direct distribution involves the manufacturers of MRO components supplying the products directly to the OEMs by eliminating the channel members. Thus, the procurement cost is less for the production companies as well as MRO service providers. However, inventory management is a crucial task as the prices associated with the products witness fluctuations in the context of raw materials.

Indirect distribution of MRO components involves multiple entities, such as manufacturers, wholesalers, distributors, retailers, and end-users or OEMs. Multiple levels of distributors and wholesalers are present in the supply chain, thus impacting the pricing structure of the MRO components used in various operations. Authorized dealers are involved in the distribution of all types of products offered by a particular company, which, in turn, aids them in providing personalized services to consumers with detailed information on each product. In Europe, MRO service providers prefer the procurement of required components from authorized distributors that ensure product quality and timely delivery.

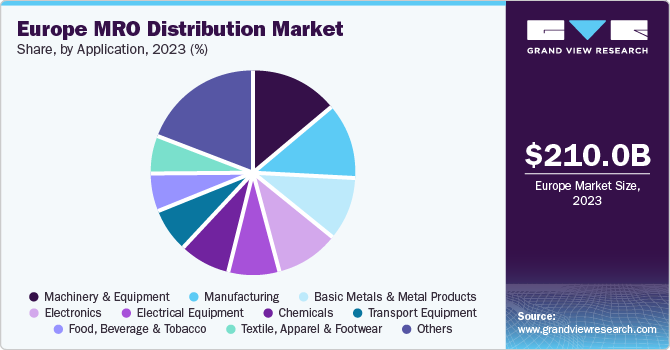

Application Insights

The machinery & equipment manufacturing application segment led the market in 2021 and accounted for the second-highest revenue share of more than 12.5%. The manufacturing of machinery and equipment is one of the most competitive and largest manufacturing segments in Europe. The presence of a large machinery manufacturing segment generates huge demand for maintenance & repair equipment and periodic services. Europe is among the leading machinery manufacturing regions globally. From the point of foreign investors, domestic demand itself offers excellent growth opportunities. The overseas industry players can be a part of this industry and become an important part of its value chain with various strengths in a varied range of verticals.

The electrical and electronic manufacturing sector in Europe is undergoing several changes and adopting new technologies in manufacturing facilities. The rising need for advanced technology equipment in household and commercial applications has compelled manufacturers to make necessary adoptions in the production processes. This has positively influenced the market for MRO operations. The pharmaceutical industry in Europe is anticipated to grow over the forecast period on account of government initiatives for new treatment facilities for circulatory system diseases, neoplasms, and respiratory diseases. The related MRO services are anticipated to increase in the coming years as pharmaceutical companies are focusing on efficient maintenance of equipment and machinery in the facilities.

Country Insights

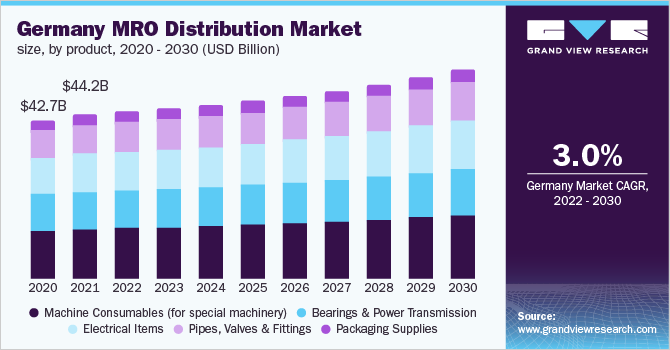

德国主导的市场,占了铁道部e than 21.5% of the overall revenue share in 2021. Industries contributing to the economic growth of the country include automotive, metal, coal,machine tools, optics,textile, plastic goods, chemical, electrical equipment, ship, high precision equipment, and pharmaceutical. The food & beverage industry in Italy is anticipated to grow at a steady CAGR over the forecast period. Growing international demand for specialty food, such as pasta andbakery products, is likely to have a positive outlook. Increasing production of food products and packaged food is anticipated to support the market growth over the forecast period. The chemical industry in France produces organic & inorganic products, pharmaceuticals, fine chemicals,perfumes, and others.

The availability of hydroelectricity and the presence of coal mines in the country have attracted chemical companies to establish their plants in these locations. Moreover, the players engaged in the production ofpetrochemicalshave established their units in areas close to Marseille in the south and Le Havre in Normandy. The automobile and machinery manufacturing industries in Finland mainly cater to the applications in military vehicles, trucks, buses, tractors, forest machines, and other motor production. Maintenance and repair operations-related to the motor machines are handled by the manufacturer or the third-party MRO service providers. Moreover, the country has at least eight shipyards that support MRO-related operations frequently.

Key Companies & MarketShare Insights

Prominent participants in the market focus on the investments to develop new technologies for product manufacturing and strengthen various stages in the value chain to enhance businesses across several application industries. These players also have adopted strategies including new product development, expansion of distribution channel, product portfolio expansion, and others. For instance, Valeo Services collaborated with Dana Inc. to develop 48V end-to-end systems for electric and hybrid vehicles. Some of the prominent players in the Europe MRO distribution market include:

Cromwell Group (Holdings) Ltd.

Graco Inc.

WABCO

Mento AS

Valeo Service U.K. Ltd.

Ascendum

Bodo Möller Chemie GmbH

Lindberg & Lund AS

MCtechnics

Neumo-Egmo Spain SL

Gazechim复合材料没有rden AB

Plastorgomma Srl

Norwegian Oilfield Supply AS

Kron CIS GmbH

Elmbridge Supplies Company Ltd.

Mates Italiana SRL

ABIC Kemi AB, Ferguson plc

RS Components

Transfer Multisort Elektronik Sp. z.o.o.

Premier Farnell, Sonepar

Wurth Group

Lapp Group

Weidmüller Interface GmbH & Co. KG

Pepperl+Fuchs AG

ebm-papst Group

WAGO Kontakttechnik GmbH & Co. KG

Rittal GmbH & Co. KG

Phoenix Contact

Schneider Electric

Panasonic Industry Europe GmbH

Festo AG & Co. KG

ABB Group

Rohde & Schwarz

Fluke Corporation

Testo SE & Co. KGaA

BENNING Elektrotechnik und Elektronik GmbH & Co. KG

Wera Werkzeuge GmbH

RUBIX

Descours & Cabaud

Eriks Group

Europe MRO DistributionMarket Report Scope

Report Attribute |

Details |

Market size value in 2022 |

USD 206.13 billion |

Revenue forecast in 2030 |

USD 259.16 billion |

Growth rate |

CAGR of 2.8% from 2022 to 2030 |

Base year for estimation |

2021 |

Historical data |

2017 - 2020 |

Forecast period |

2022 - 2030 |

Quantitative units |

Revenue in USD million/billion and CAGR from 2022 to 2030 |

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

Segments covered |

Product, sourcing/service type, maintenance type, application, distribution channel, country |

Regional scope |

Europe |

Country scope |

Germany; France; Italy; The Netherlands; Belgium; Switzerland; Sweden; Denmark; Poland; Austria; Finland; Czech Republic; Hungary; Slovakia |

Key companies profiled |

Cromwell Group (Holdings) Ltd.; Graco Inc.;WABCO;Mento AS; Bodo Möller Chemie GmbH; Lindberg & Lund AS; MCtechnics; Neumo-Egmo Spain SL; Gazechim Composites Norden AB; Plastorgomma Srl; Rittal GmbH & Co. KG; Phoenix Contact; Schneider Electric; Panasonic Industry Europe GmbH; Festo AG & Co. KG; ABB Group; Rohde & Schwarz; Fluke Corporation.; Testo SE & Co. KGaA; BENNING Elektrotechnik und Elektronik GmbH & Co. KG; Wera Werkzeuge GmbH; RUBIX; Descours & Cabaud; Eriks Group |

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Segments Covered in the Report

This report forecasts revenue growth at regional and country levels and provides an analysis of the latest industry trends in each of the segments from 2017 to 2030. For the purpose of this study, Grand View Research has segmented the Europe MRO distribution market report on the basis of product, sourcing/service type, maintenance type, application, distribution channel, and country:

Product Outlook (Revenue, USD Million,2017 - 2030)

Bearings & Power Transmission

Pipes, Valves & Fittings

Electrical Items

Packaging Supplies

Machine Consumables

Sourcing/Service Type Outlook (Revenue, USD Million,2017 - 2030)

Internal MRO

External MRO

Maintenance Type Outlook (Revenue, USD Million,2017 - 2030)

Preventive/Scheduled Maintenance

Corrective Maintenance

Distribution Channel Outlook (Revenue, USD Million, 2017 - 2030)

Direct

Indirect

Application Outlook (Revenue, USD Million,2017 - 2030)

Food, Beverage & Tobacco

Textile, Apparel & Footwear

Wood & Paper

Mining, Oil & Gas

Basic Metals & Metal Products

Rubber, Plastic & Non-metallic Products

Chemicals

Pharmaceuticals

Electronics

Machinery & Equipment

Electrical Equipment

Transport Equipment

Manufacturing

Others

Country Outlook (Revenue, USD Million,2017 - 2030)

Czech Republic

Hungary

Slovakia

Austria

Finland

France

Germany

Italy

Belgium

The Netherlands

Poland

Sweden

Denmark

Switzerland

Frequently Asked Questions About This Report

b.The Europe MRO distribution market size was estimated at USD 202.88 billion in 2021 and is expected to reach USD 206.13 billion in 2022.

b.The Europe MRO distribution market is expected to grow at a compounded annual growth rate of 2.8% from 2022 to 2030 to reach USD 259.16 billion in 2030.

b.Germany dominated the Europe MRO distribution market with a share of 21% in 2021. The development of various end-use sectors in the region, including manufacturing, construction, chemicals, and electronics, is expected to emerge as a major factor driving market growth.

b.Some key players operating in the Europe MRO distribution market include Graco, Inc.; WABCO; Kayden Corporation; Cromwell Group; and Bodo Moller Chemie GmbH.

b.Key factors driving the Europe MRO distribution market growth include the increasing manufacturing and industrialization rates in countries such as Finland, Norway, Germany, and Sweden are anticipated to drive the demand for Maintenance, Repair, Operations (MRO) services for equipment and products.